As a professional CNC Machining service provider, EMAR specializes in delivering precision aluminum components for industries ranging from aerospace to automotive. This comprehensive guide explores the complete CNC aluminum parts processing workflow to help technical buyers and engineers understand critical manufacturing considerations.

1. Material Selection for CNC Aluminum Machining

The process begins with choosing the right aluminum alloy. Common grades include 6061 (general purpose), 7075 (high strength), and 5052 (corrosion resistance). Our engineers at EMAR analyze your application requirements to recommend optimal materials that balance machinability, strength, and cost-effectiveness.

2. Precision CNC Programming Techniques

Our CNC machining experts use advanced CAM software to create optimized toolpaths. Key considerations include:

- Cutting speed optimization (typically 500-300 RPM for aluminum)

- Feed rate calibration (.05-.2mm/tooth)

- Coolant strategy selection (flood cooling vs. MQL)

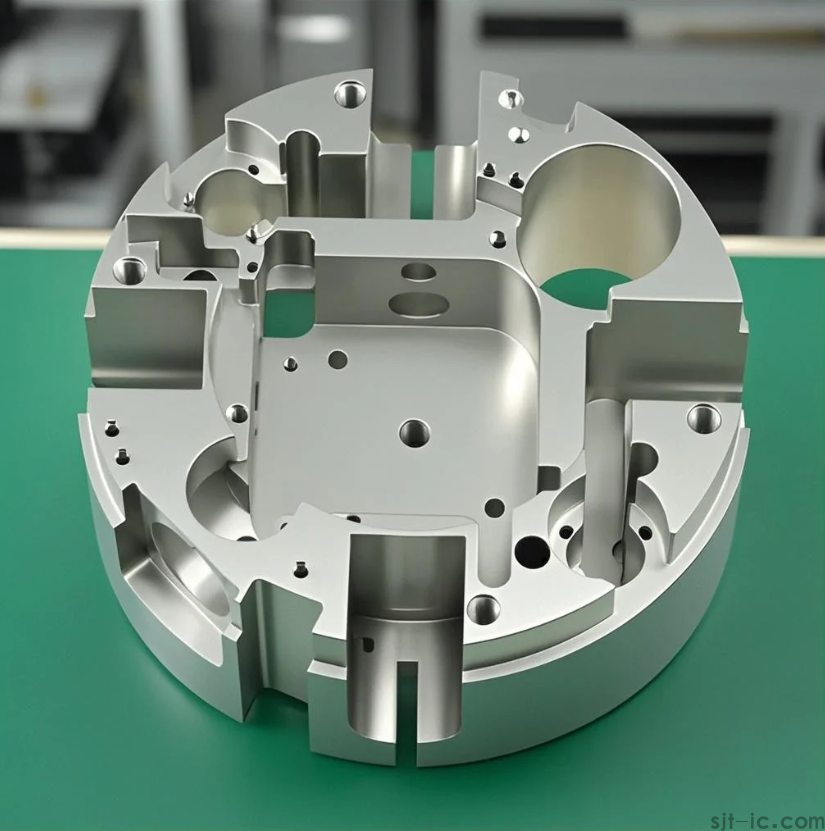

3. Machining Process Breakdown

The core CNC aluminum parts processing stages include:

- Facing: Achieving perfect surface flatness

- Contouring: Creating complex 3D geometries

- Drilling/Tapping: Precision hole-making

- Threading: Creating accurate screw threads

4. Quality Control Protocols

EMAR implements rigorous inspection procedures using CMM machines, surface roughness testers, and optical comparators. We maintain ±.01mm tolerance standards for critical dimensions, with full documentation including material certifications and inspection reports.

5. Post-Processing Options

To enhance functionality and aesthetics, we offer:

- Anodizing (Type II/III)

- Powder coating

- Laser engraving

- Electroplating

With 15+ years of experience in CNC machining, EMAR delivers aluminum components that meet the strictest industry standards. Visit our website at https://www.sjt-ic.com/ to request a free project evaluation and DFM analysis today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque