Understanding CNC Small Parts Machining

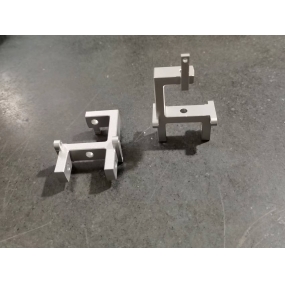

CNC small parts machining refers to the precision manufacturing of miniature components using computer numerical control technology. This specialized process enables EMAR to produce intricate parts with tight tolerances, typically ranging from .5mm to 50mm in size. Our advanced CNC Machining centers achieve micron-level precision, making this solution ideal for industries requiring small, complex components.

Key Advantages of Our Small Parts Machining

EMAR's CNC small parts machining capabilities offer several distinct benefits:

- ±.005mm tolerance accuracy for critical dimensions

- High repeatability across production batches

- Capability to machine complex geometries in one setup

- Material versatility including aluminum, stainless steel, brass, and engineering plastics

Our Comprehensive Machining Process

The CNC small parts machining process at EMAR follows these critical steps:

- Material selection and verification

- Precision fixturing design for small components

- Multi-axis simultaneous machining

- In-process quality inspection

- Final surface finishing and deburring

Industry Applications

Our small parts machining serves diverse sectors including medical devices (surgical instruments), electronics (connectors), aerospace (sensor components), and automotive (fuel injection parts). The ability to maintain precision at miniature scales makes our services particularly valuable for prototyping and high-volume production of small components.

Why Choose EMAR for Your Small Parts Needs

With specialized Swiss-type CNC machines and micro-machining centers, EMAR delivers unparalleled precision for small part manufacturing. Our engineers optimize every machining parameter - from spindle speeds to tool paths - ensuring optimal results for your most demanding small component requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque