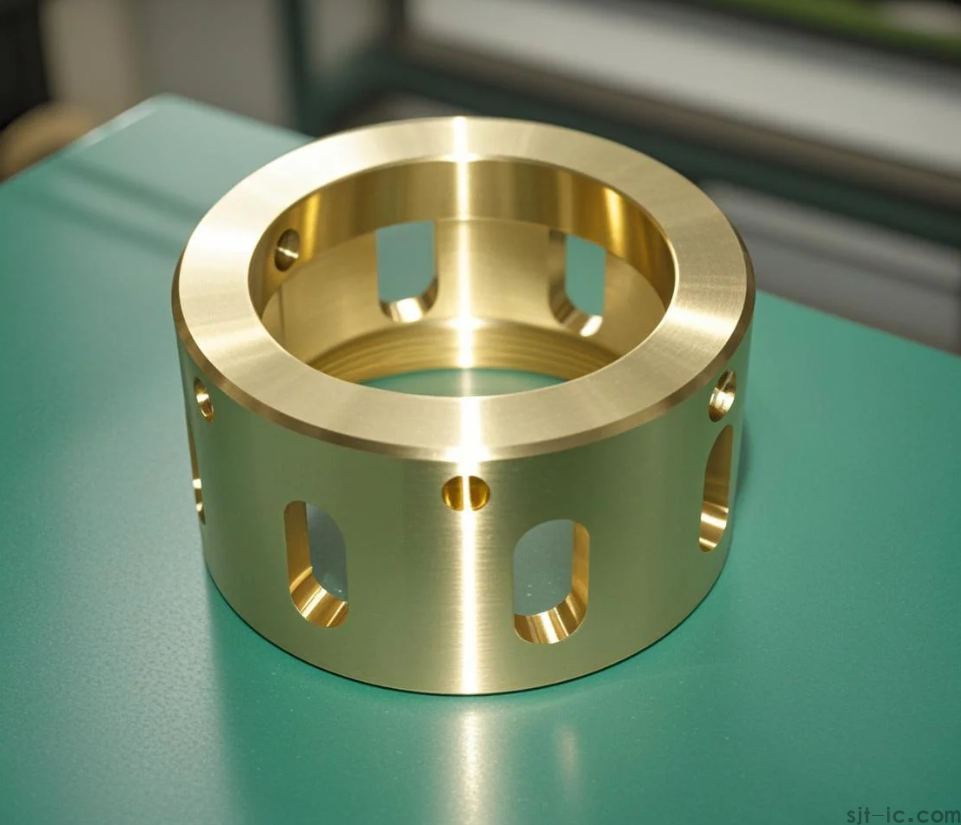

As a leading CNC Machining service provider, EMAR specializes in precision brass component manufacturing. This article will explore the technical nuances of brass machining and how our advanced capabilities deliver exceptional results for industrial applications.

Understanding Brass as a Machining Material

Brass alloys (particularly C36000 free-cutting brass) are preferred for CNC machining due to their excellent machinability, corrosion resistance, and electrical conductivity. With 100% machining yield rating, brass outperforms most metals in CNC operations.

Key Steps in CNC Brass Machining Process

Our certified process at EMAR includes:

1. Material selection and verification

2. Precision toolpath programming

3. High-speed milling/turning operations

4. Automated quality inspection

5. Surface finishing (optional)

Technical Advantages of Our Brass Machining

We achieve ±.005mm tolerances using:

• Swiss-type CNC lathes for complex geometries

• Micro-grain carbide tooling

• High-pressure coolant systems

• In-process gauging systems

Why Choose EMAR for Your Brass Components

Our CNC machining brass process delivers:

✓ 30% faster cycle times than industry average

✓ 99.8% first-pass yield rate

✓ Full material traceability

✓ ISO 9001:2015 certified production

Contact our engineering team at www.sjt-ic.com to discuss your brass machining requirements and receive DFM analysis within 24 hours.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque