Understanding CNC Cast Steel Machining

CNC cast steel machining is a specialized manufacturing process that combines the durability of cast steel with the precision of computer numerical control technology. This process is particularly valuable for industries requiring high-strength components with complex geometries, such as automotive, aerospace, and heavy machinery sectors.

Key Stages in the CNC Cast Steel Machining Process

The complete CNC Machining process for cast steel involves several critical stages:

1. Material Selection: Choosing the appropriate cast steel grade based on mechanical property requirements and application environment.

2. Pre-Machining Preparation: This includes cleaning, inspection, and sometimes stress relieving of the cast steel components.

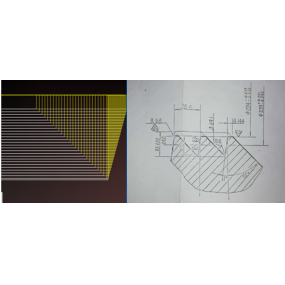

3. CNC Programming: Creating precise tool paths using CAD/CAM software to ensure dimensional accuracy.

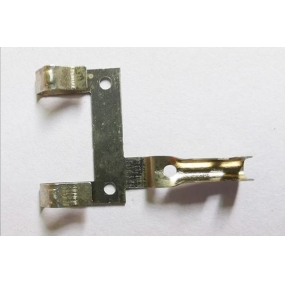

4. Machining Operations: Executing turning, milling, drilling, or grinding operations with CNC equipment.

5. Quality Control: Implementing rigorous inspection protocols including CMM measurements and surface finish analysis.

Technical Considerations for Optimal Results

When performing CNC machining on cast steel, several technical factors must be addressed:

- Tool Selection: Carbide or ceramic cutting tools with appropriate coatings to handle cast steel's hardness.

- Cutting Parameters: Optimizing spindle speeds, feed rates, and depth of cut to balance productivity and tool life.

- Coolant Application: Proper cooling to manage heat generation and prevent workpiece distortion.

- Surface Treatment: Post-machining processes like shot peening or heat treatment when required.

EMAR's Expertise in CNC Cast Steel Machining

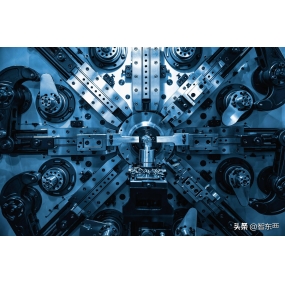

At EMAR, we've perfected our cast steel machining capabilities through years of experience and continuous investment in advanced CNC equipment. Our facility features:

- Multi-axis CNC machining centers capable of handling large cast steel components.

<p- In-process measurement systems for real-time quality assurance.

- Skilled technicians with extensive material knowledge to optimize every machining operation.

We understand that cast steel components often serve critical functions in demanding applications, which is why we maintain the highest standards throughout our machining processes.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque