With the widespread application of lightweight metals, CNC aluminum processing is becoming a choice for many industries. With our extensive processing capabilities and experience, CNC Machining of aluminum alloys has been a field of expertise for many years at Zhongxie.

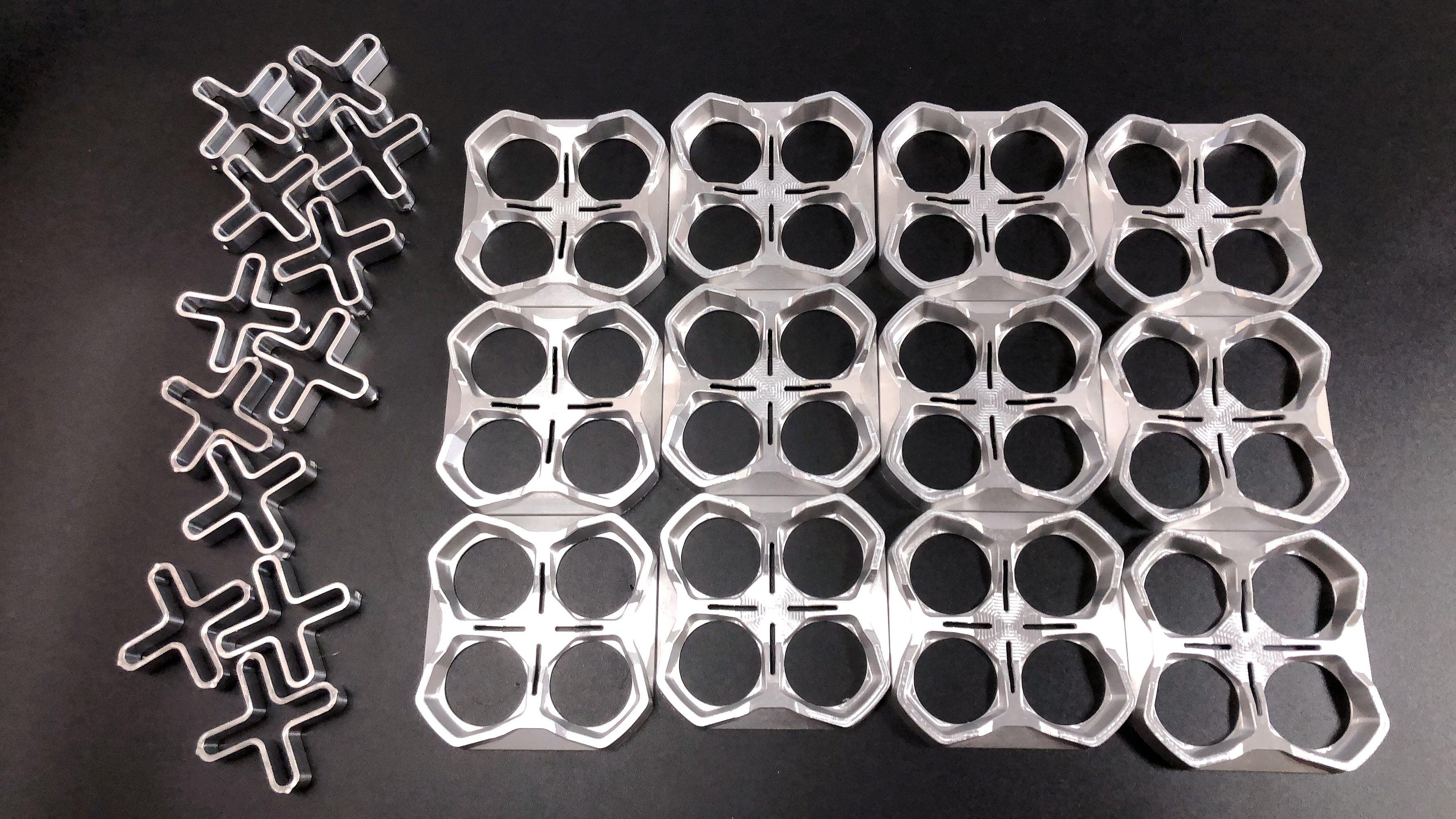

We focus on the manufacturing of non-standard precision aluminum parts with complex structures and are committed to delivering highly accurate and consistent parts to our customers. We continuously invest in new equipment and skilled employees to ensure that our team maintains a strong competitive advantage. We have also been improving aluminum processing technology to enhance efficiency and quality, and continuously meet our customers' production needs!

Are you looking for a processing method that can quickly implement design ideas? Our Shenzhen Zhonghe Union professional aluminum alloy CNC machining service is exactly what you need! We not only provide full process services from sampling to batch processing of final products, but also focus on handling complex non-standard precision aluminum parts.

✨ Customized aluminum parts batch processing ✨

If you need assistance with customized aluminum machining projects, our expertise in CNC aluminum machining will be one of the most capable and affordable supplier resources for you. We strictly adhere to the ISO9001 quality system standard, combined with efficient production processes and flexible customized engineering, enabling us to deliver complex projects in a shorter turnaround time and provide excellent product quality. We also provide typical surface treatments for customized aluminum processing parts, such as sandblasting, electroplating, polishing, oxidation, electrophoresis, powder coating, spray painting, etc.

Whether it's automotive manufacturing, medical equipment, or industrial design, we can provide precise and efficient solutions for your needs.

Fine craftsmanship, quality first

We understand the importance of every detail, so we invest in advanced equipment and skilled technicians to ensure that every component meets the highest standards.

By using the correct feed rate, spindle speed, and cutting depth, we ensure that the machining process of each product can be stable and maintain high-quality output.

Technological innovation leads the future

✨ Advantages of Aluminum Alloy Machining ✨

High strength and lightweight

Excellent machining performance

Excellent corrosion resistance

Higher conductivity

Surface treatment and anodizing

Lower production costs

Recyclability

000'Ama Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes businesses such as CNC machining parts, metal stamping parts, and sheet metal processing.

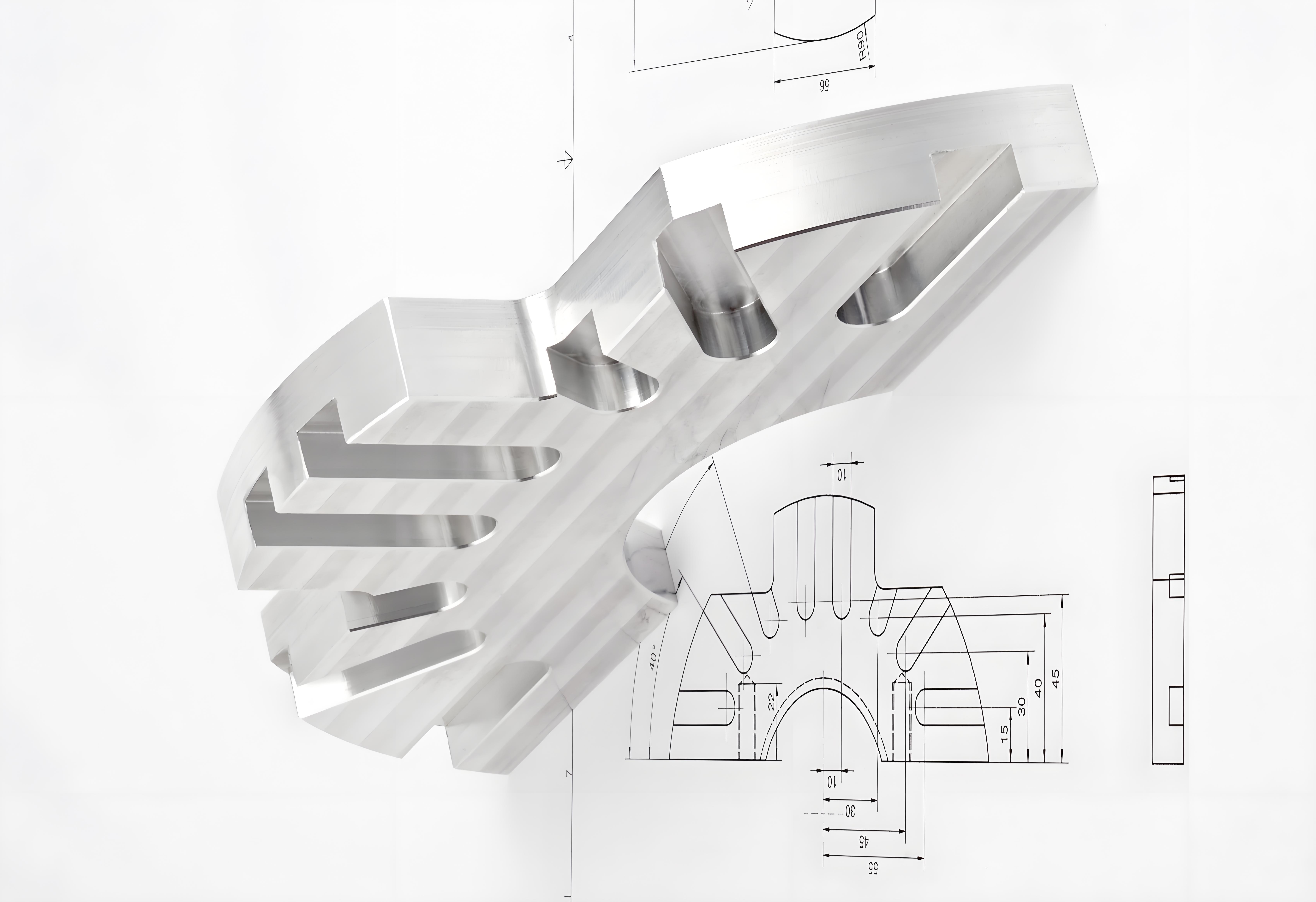

Here, every CNC high-speed cutting is a challenge and breakthrough to the limits of technology.

From rough machining to precision machining, every step is precisely controlled to ensure that every component can perfectly present the original design intention.

We constantly explore new processing technologies to adapt to changing industrial demands and help your products stay ahead in the market.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque