In today's manufacturing industry, customer needs are crucial. With the continuous development of technology, aluminum alloy five axis machining has become one of the important methods for machining high-precision complex parts. This article will explore how aluminum alloy five axis machining can meet customer needs, focusing on aspects such as quality, cost, delivery time, and personalized requirements.

1. Quality

Aluminum alloy five axis machining can provide high-precision machining quality while ensuring product stability. By utilizing CNC technology and high-precision machine tools, the machining process can be precisely controlled, thereby reducing errors. In addition, by using high hardness alloy cutting tools and precise cutting parameters, machining efficiency and product quality can be effectively improved.

2. Cost

Aluminum alloy five axis machining has high production efficiency and can reduce production costs. Due to its ability to process multiple parts at once, it reduces clamping and debugging time, thereby improving production efficiency. In addition, by adopting CNC programming technology, the impact of human factors on the production process can be greatly reduced, further reducing costs.

3. Delivery time

Aluminum alloy five axis machining can quickly provide customers with high-precision complex parts they need. Due to its high degree of automation, it can quickly complete the processing of a large number of complex parts. Meanwhile, through the adoption of a production management system, real-time monitoring and flexible adjustment of production progress can be achieved, thereby ensuring the delivery time required by customers.

4. Personalized needs

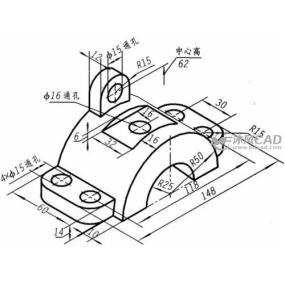

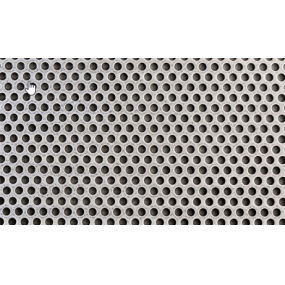

Aluminum alloy five axis machining has high flexibility and can meet customers' personalized needs. Due to its strong programmability, customized design and production can be carried out according to customer needs. In addition, by using multiple materials and surface treatment techniques, we can provide customers with a diverse range of product choices.

Aluminum alloy five axis machining has the advantages of high precision, high efficiency, fast delivery, and personalized customization, which can meet the diverse needs of customers. In today's manufacturing industry, aluminum alloy five axis machining has become one of the essential technologies to meet customer needs. In order to better meet the needs of customers, it is suggested that enterprises should strengthen technology research and development and talent cultivation, and improve the technical level and application ability of aluminum alloy five axis machining. At the same time, strengthen communication and collaboration with customers, timely understand their needs, and make corresponding improvements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque