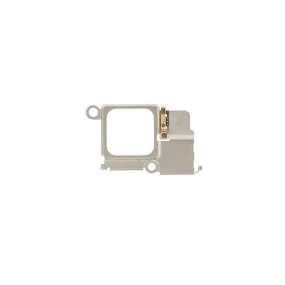

When it comes to Metal Stamping parts, such as some injection hole sealing nails that we often use in our daily lives, these hardware parts are very good in terms of operation technology and safety performance. If you want these injection hole sealing nail hardware components to have good technical safety performance, then the stamping process needs to start with technical measures to improve the rationality and qualification of the hardware mold.

The qualification and stable performance during production of a hardware component are very important, as they can reduce losses and save costs. The commonly referred to metal stamping parts are the process of using punches and molds to deform or fracture metal sheets such as iron and aluminum, as well as dissimilar materials, to form a specific shape.

It can be seen that there are some similarities between metal stamping parts and sheet metal forming, but there are also differences. When designing these hardware components, manufacturers can combine the material with the rationality of the mold and the lifespan of the stamping mold. Comprehensive design should be carried out from the aspects of stable production and qualified quality of metal stamping parts.

So, the stamping technology of injection hole sealing nail hardware stamping parts is very important. In addition, equipment debugging, installation, and handling are also important. Moreover, the selection of materials is the preferred factor affecting the quality of the sealing nail hardware for injection holes, as the choice of materials plays a crucial role in affecting product quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque