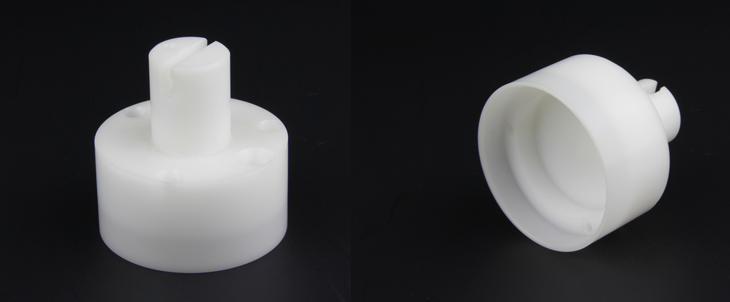

Due to different industries, many fields require the use of POM material for component production. Therefore, machining manufacturers often see POM precision machined component products. Before processing, we need to understand the advantages of this material. EMAR Precision Technology is committed to the precision machining of POM component products and has summarized a large amount of information. The main advantages of POM material are as follows:

1. High mechanical strength and rigidity;

2. Excellent environmental resistance and resistance to organic solvents;

3. The highest fatigue strength;

4. Strong resistance to repeated impacts;

5. Good electrical properties;

6. Wide temperature range for use (-40 ℃~120 ℃);

7. Good resilience;

8. Excellent dimensional stability;

9. Has good self lubrication and wear resistance.

Its entire process: polyoxymethylene thermoplastic crystalline polymer. It is called "super steel" or "Sai steel", also known as polyoxymethylene. The English abbreviation is POM. The polymer obtained by formaldehyde polymerization usually has a low degree of polymerization and is prone to thermal depolymerization. It can be used as a raw material for organic chemicals, synthetic resins, and also as a drug fumigant.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque