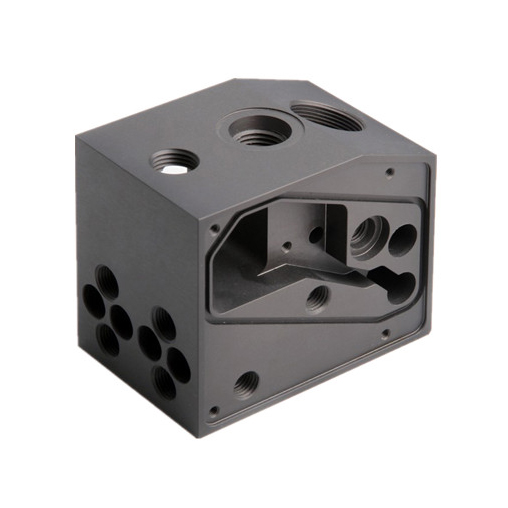

CNC five axis machining technology is a high-precision and high-efficiency machining technology, which is of great significance for improving the competitiveness of the manufacturing industry. CNC five axis machining technology is widely used in aerospace, automotive, mold, medical equipment and other fields, bringing higher precision and production efficiency to the manufacturing industry. So, let's take a look at the advantages of CNC five axis machining technology, which are mainly reflected in the following aspects: The ability to machine complex parts: Five axis machining can freely move the tool in multiple directions, handle complex surfaces and angles, such as aircraft parts, car body parts, turbine blades, etc. The flexibility of this processing method makes five axis machining particularly suitable for manufacturing parts with complex surfaces, multiple angles, or very precise requirements Improve machining accuracy and efficiency: During the five axis machining process, the workpiece does not move, which can achieve higher part accuracy. Meanwhile, due to the ease of processing complex shapes in one setup, five axis machining helps reduce setup and manufacturing time, and improve productivity Good smoothness: The use of shorter cutting tools in the five axis machining process helps achieve excellent surface smoothness, resulting in better part quality.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque