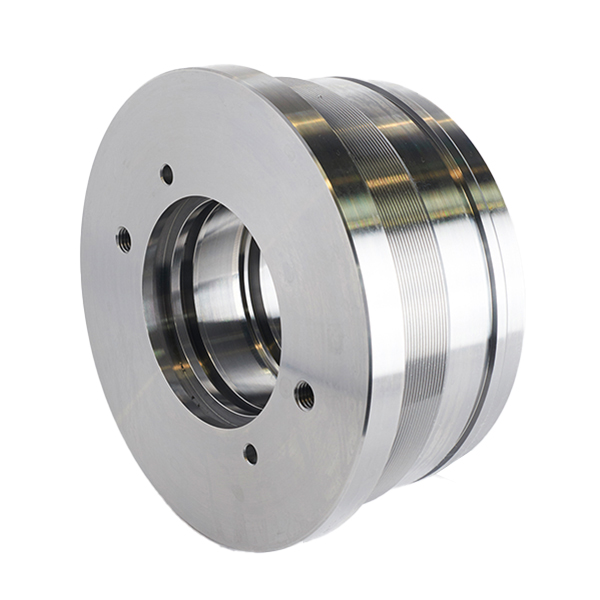

CNC numerical control machining is a method of precision machining using computer digital control technology. During machining, the control system will automatically select the tool according to the program requirements, automatically change the tool speed and feed speed, etc., so as to complete the machining of the part. CNC numerical control machining accuracy can be controlled in the following ways:  Machine tool accuracy test: Check the accuracy of the alignment and movement of the machine tool to ensure that the direction of the spindle, bracket, axis, etc. is accurate. The angle and bending of the axis must be accurate, and the linear axis should also be checked. Parts or product testing: In this mode, check the size and position of the part, including checking parameters such as positioning, surface finish and shape. Also check the dimensional and geometric tolerances according to the requirements or application. Process Monitoring: Check the process steps at each stage to avoid process-related errors that can lead to defective products or unnecessary manufacturing delays. The above methods are for reference only. It is recommended to consult a professional for more accurate information.

Machine tool accuracy test: Check the accuracy of the alignment and movement of the machine tool to ensure that the direction of the spindle, bracket, axis, etc. is accurate. The angle and bending of the axis must be accurate, and the linear axis should also be checked. Parts or product testing: In this mode, check the size and position of the part, including checking parameters such as positioning, surface finish and shape. Also check the dimensional and geometric tolerances according to the requirements or application. Process Monitoring: Check the process steps at each stage to avoid process-related errors that can lead to defective products or unnecessary manufacturing delays. The above methods are for reference only. It is recommended to consult a professional for more accurate information.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque