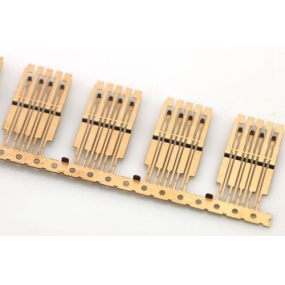

Insight! Precision cold extrusion miniature hardware parts can be produced at such a high speed! This is not a myth! It is the technical crystallization developed by the engineers of EMAR Hardware Co., Ltd. after a thousand days and nights. EMAR Hardware began to develop precision cold extrusion technology in 2010, and the craftsman spirit around the clock changed the various processes completed by the ordinary cold extrusion branch to the continuous mold precision feeding process, and in the exploration of the mold structure optimization design, extending the service life of the mold and other processes It has become increasingly perfect on the road to finally achieve today‘s precision cold extrusion technology. The current precision cold extrusion technical indicators are: the product precision can reach 0.02mm, the daily output of a single mold can reach 200,000 particles, which can be used for iron-nickel alloys, stainless steel, low carbon steel, hard aluminum, oxygen-free copper, copper and other metal materials. Precision cold extrusion processing, the damage repair of key parts of the mold has been extended from the first 3 days to the present 15 days. Technological advancements, never-ending, precision cold extrusion technology, EMAR is always on the run!

Insight! Precision cold extrusion miniature hardware parts can be produced at such a high speed! This is not a myth! It is the technical crystallization developed by the engineers of EMAR Hardware Co., Ltd. after a thousand days and nights. EMAR Hardware began to develop precision cold extrusion technology in 2010, and the craftsman spirit around the clock changed the various processes completed by the ordinary cold extrusion branch to the continuous mold precision feeding process, and in the exploration of the mold structure optimization design, extending the service life of the mold and other processes It has become increasingly perfect on the road to finally achieve today‘s precision cold extrusion technology. The current precision cold extrusion technical indicators are: the product precision can reach 0.02mm, the daily output of a single mold can reach 200,000 particles, which can be used for iron-nickel alloys, stainless steel, low carbon steel, hard aluminum, oxygen-free copper, copper and other metal materials. Precision cold extrusion processing, the damage repair of key parts of the mold has been extended from the first 3 days to the present 15 days. Technological advancements, never-ending, precision cold extrusion technology, EMAR is always on the run!

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque