Precision casting, precision molding, plastic processing, and thin plate precision forming technologies are highly valued in industrialized countries, and a large amount of money is invested in priority development.

In the 1970s, the US Air Force oversaw the development of the "Forging Process Modernization Program", with the aim of modernizing the important process of forging, using more CAD/CAM, and reducing the manufacturing cycle of new forgings by 75%. Shenzhen Precision Parts Processing In 1992, the US Department of Defense proposed the "Military Key Technology List", which included isobaric forming processes, numerical control computer-controlled spinning, plastic transformation and shear forming machines, superplastic forming/diffusion joining processes, and hydraulic extension forming processes. Precision plastic forming processes.

In the 1970s, the US Air Force oversaw the development of the "Forging Process Modernization Program", with the aim of modernizing the important process of forging, using more CAD/CAM, and reducing the manufacturing cycle of new forgings by 75%. Shenzhen Precision Parts Processing In 1992, the US Department of Defense proposed the "Military Key Technology List", which included isobaric forming processes, numerical control computer-controlled spinning, plastic transformation and shear forming machines, superplastic forming/diffusion joining processes, and hydraulic extension forming processes. Precision plastic forming processes.

In recent years, foreign countries have also developed "forging of large die forgings and blade precision forging processes", "rapid solidification powder lamination process", "power spinning forming process for large and complex structural parts", "superplastic forming process for difficult-to-deform materials", "advanced material forming process", etc. Our country‘s superplastic forming technology is also applied in the aerospace and machinery industries, such as satellite parts, missiles and rocket gas cylinders in the aerospace industry. Superplastic forming is used to manufacture the Qin alloy recovery chamber of reconnaissance satellites.

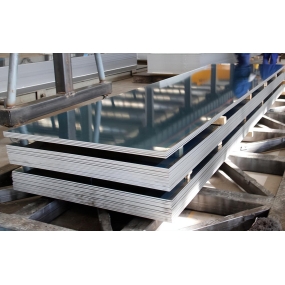

At the same time, it has basically mastered the superplastic forming process of zinc, copper, aluminum, and Qin alloy. The minimum forming thickness can reach 0.3mm, and the shape is also more complicated. In addition, precision molding technology has been widely used abroad to manufacture weapons. Commonly used precision parts processing and molding technology, such as occlusion forging, precision forming using shunt principle, and isothermal forming, have been used in military production abroad. Shenzhen Precision Parts Processing At present, precision molding technology is less used in our country, and the accuracy is poor. The accuracy abroad is 0.05-0.10mm, and our country is 0.1-0.25mm.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque