As a leading provider of CNC automation parts processing, EMAR delivers high-precision machined components for industries ranging from robotics to aerospace. This article explores the technical advantages, quality control measures, and industry-specific applications of our automated CNC Machining services.

What is CNC Automation Parts Processing?

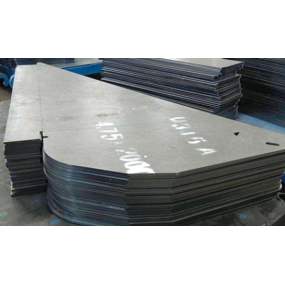

CNC automation parts processing refers to the manufacturing of precision components using computer-controlled machines with minimal human intervention. Our facility at EMAR utilizes advanced 5-axis CNC machines capable of producing complex geometries with tolerances as tight as ±.005mm. This automated approach ensures consistent quality across high-volume production runs while reducing lead times by 30-40% compared to conventional machining.

Key Advantages of Our Automated CNC Solutions

1. 24/7 Production Capability: Our automated cell runs continuously with robotic part loading/unloading

2. Enhanced Precision: In-process measurement systems maintain micron-level accuracy

3. Material Versatility: Processes aluminum alloys, stainless steels, titanium, and engineering plastics

4. Scalable Solutions: From prototype batches to 50,000+ unit production runs

Quality Assurance in Automated Machining

EMAR implements a rigorous quality management system featuring:

- CMM inspection for dimensional verification

- Surface roughness measurement (Ra .4-3.2 μm achievable)

- Material certification and traceability

- First-article inspection reports for every new part number

Our CNC automation parts processing capabilities are particularly valued in industries requiring complex, high-tolerance components such as medical devices, semiconductor equipment, and automotive subsystems. The combination of advanced machine tools, cutting-edge CAM programming, and automated quality control positions EMAR as your ideal manufacturing partner.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque