What equipment is required for stainless steel Sheet Metal Processing? Let‘s take a look with the editor today.

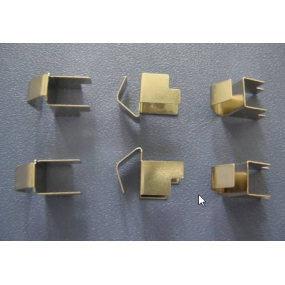

1. Cutting equipment: general cutting machine, numerical control machine tool cutting machine, three-dimensional manipulator laser cutting machine, numerical control machine

2. Forming equipment: general stamping machine, mesh machine, folding machine and numerical control machine tool folding machine.

3. Electric welding equipment: argon arc welding machine, carbon dioxide maintenance welding machine, spot welding machine, intelligent machine human welding machine.

4. Surface treatment equipment: wire drawing machine, sandblasting machine, grinding and polishing machine, electroplating process tank, air oxidation tank paint baking process line

5. Shaping equipment: leveling machine.

According to a definition in an overseas technical journal, it can be defined as: Sheet metal parts are a comprehensive cold-drawn processing process for metal sheets (usually below 6mm), including shearing, punching/cutting/composite, folding, riveting, piecing, forming (such as vehicle bodies), etc. Its significant feature is that the same part is of uniform thickness.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque