Precision copper machining is a complex process that requires high-end technical and equipment support. The following is an introduction and analysis of the characteristics of precision copper machining:

Precision copper processing first requires the selection of high-quality copper materials, such as high-purity copper, which have good electrical conductivity, thermal conductivity, corrosion resistance and plasticity. During processing, the quality of materials and processing parameters need to be strictly controlled to ensure the accuracy and quality of the final product.

Precision copper processing first requires the selection of high-quality copper materials, such as high-purity copper, which have good electrical conductivity, thermal conductivity, corrosion resistance and plasticity. During processing, the quality of materials and processing parameters need to be strictly controlled to ensure the accuracy and quality of the final product.

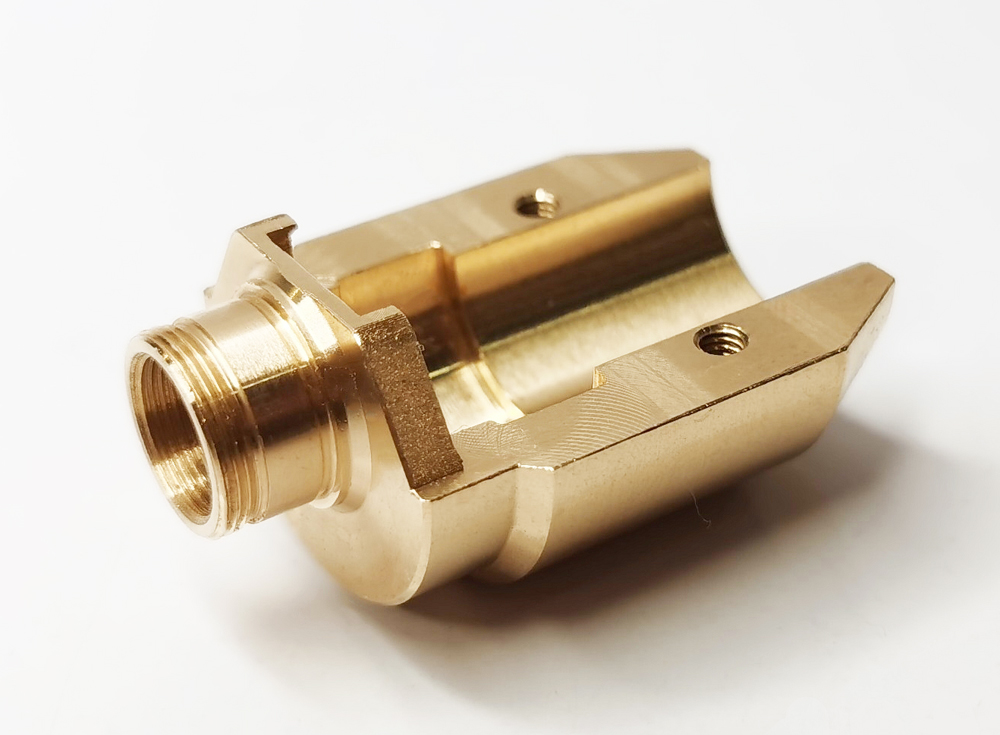

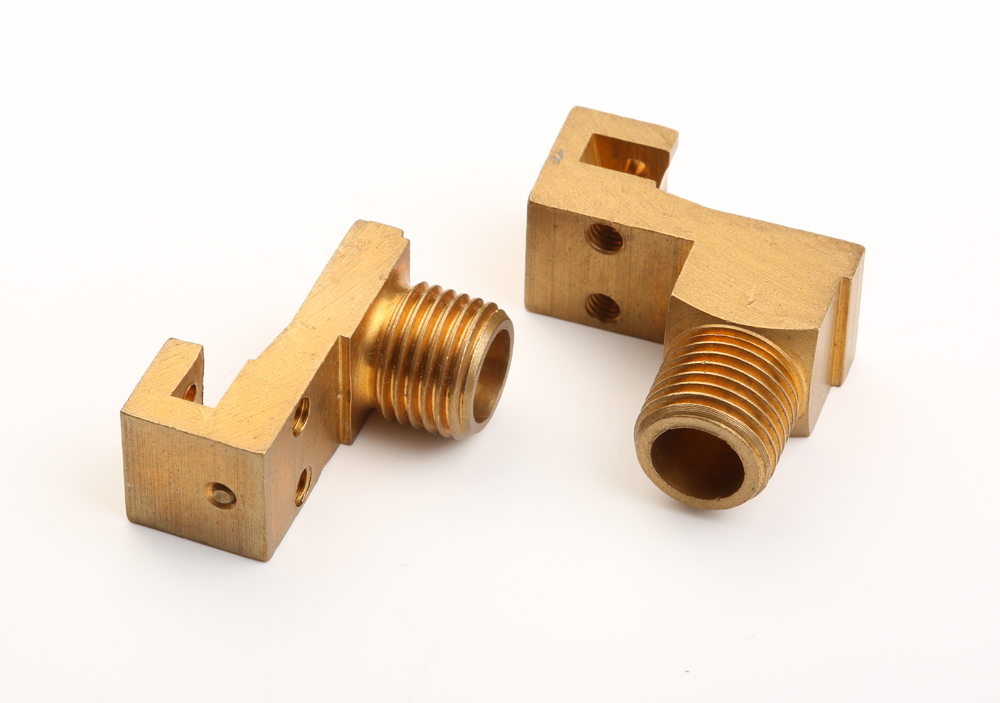

The machining process mainly includes steps such as smelting and casting, rolling and drawing, cutting and machining, and surface treatment. High-precision machining and machining control are carried out using high-precision machining equipment, such as numerical control lathes, numerical control milling machines, numerical control grinders, etc. These equipment has the advantages of high precision, high efficiency, and high stability, which can meet the requirements of precision copper machining. When machining, high-quality cutting tools, fixtures, measuring instruments, and other auxiliary tools are also required.

The characteristics of precision copper parts processing lie in its high precision and high reliability. Due to the good ductility and plasticity of copper materials, the processing is difficult, so it is necessary to adopt appropriate processing methods and processes, such as controlling the cutting feed speed, using sharp tools and cooling the workpiece, etc., to ensure the processing accuracy and quality. At the same time, the surface of copper parts is prone to oxidation, discoloration and other problems, and it is necessary to adopt appropriate surface treatment methods, such as polishing, sandblasting, electroplating, etc., to improve its corrosion resistance, aesthetics and service life.

The characteristics of precision copper parts processing lie in its high precision and high reliability. Due to the good ductility and plasticity of copper materials, the processing is difficult, so it is necessary to adopt appropriate processing methods and processes, such as controlling the cutting feed speed, using sharp tools and cooling the workpiece, etc., to ensure the processing accuracy and quality. At the same time, the surface of copper parts is prone to oxidation, discoloration and other problems, and it is necessary to adopt appropriate surface treatment methods, such as polishing, sandblasting, electroplating, etc., to improve its corrosion resistance, aesthetics and service life.

In addition, precision copper parts processing is widely used in many fields, such as machinery manufacturing, electronics industry, communication equipment and automotive industry. These fields require high precision and quality of copper parts, and precision copper parts processing can meet these requirements, providing a guarantee for the stable operation of various equipment.

In short, precision copper processing is a complex and important process that requires high-end technology and equipment support. With the progress of science and technology and the development of industry, precision copper processing will usher in a broader development prospect.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque