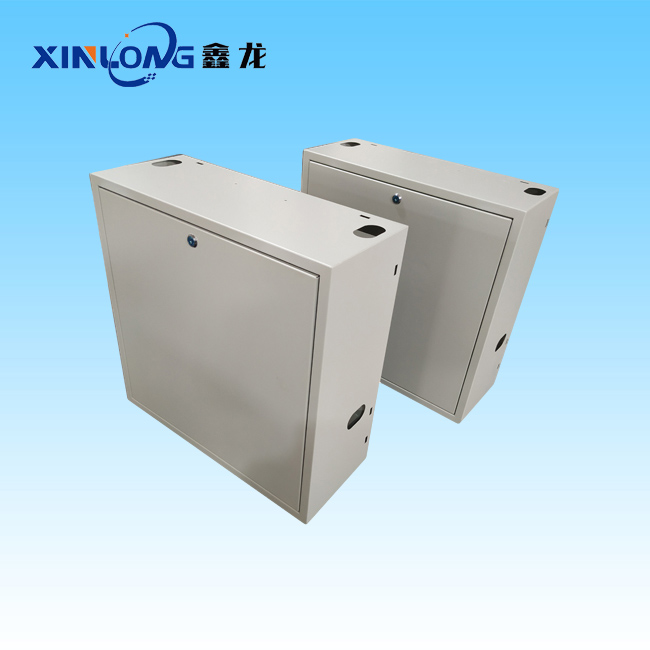

In the processing of cabinet chassis, the requirements for surface heat treatment (more commonly expressed as "surface treatment") are multi-faceted, aiming to ensure the appearance, performance, durability and safety of the cabinet chassis. The following are some of the main requirements: 1. Appearance requirements are neat and smooth: After surface treatment, the cabinet chassis should be neat and smooth in appearance, free from obvious defects and particles. Color and gloss: Color and gloss must meet the design requirements, free from obvious color difference and color spots.

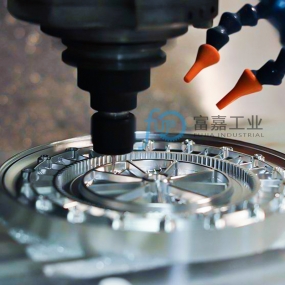

Second, performance and durability requirements Corrosion resistance: After surface treatment, the cabinet chassis should have good corrosion resistance and be able to resist corrosion factors in the environment, such as acid, alkali, salt and other substances. Wear resistance: The wear resistance of the cabinet chassis should be good and able to withstand certain friction and wear. Weather resistance: The cabinet chassis should be able to adapt to various climatic conditions, such as high temperature, low temperature, humidity, dryness and other environmental factors. Third, safety requirements Insulation: For the cabinet chassis of electrical equipment, the surface treatment should have good insulation properties to ensure the safe operation of the equipment. Fourth, process and adhesion requirements Adhesion: The coating and substrate after surface treatment should have good adhesion and not easy to fall off or foam. Exquisite craftsmanship: The process of surface treatment should be exquisite to ensure that the treatment effect is uniform and stable. Five, environmental protection requirements Environmental protection materials: The materials used in surface treatment should meet the requirements of environmental protection, no harmful substances are released, and will not cause harm to the environment and human body. Six, specific surface treatment methods In the processing of cabinets and chassis, common surface treatment methods include electrostatic powder spraying, electroplating, anodic oxidation, etc. Among them, electrostatic powder spraying is one of the surface treatment methods selected for cabinet Sheet Metal Processing because of its good adhesion and corrosion resistance. This method sends solid small particles of paint into the spray gun through compressed air. The paint particles are adsorbed on the workpiece under the action of electrostatic force to form a uniform coating film. After hot melting, leveling and curing, a hard coating film is formed.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque