As a leading CNC Machining specialist, EMAR Company delivers exceptional CNC copper processing solutions for industries requiring superior electrical/thermal conductivity. This guide explores technical considerations and our competitive advantages in handling this challenging material.

Why Choose CNC Machining for Copper Components?

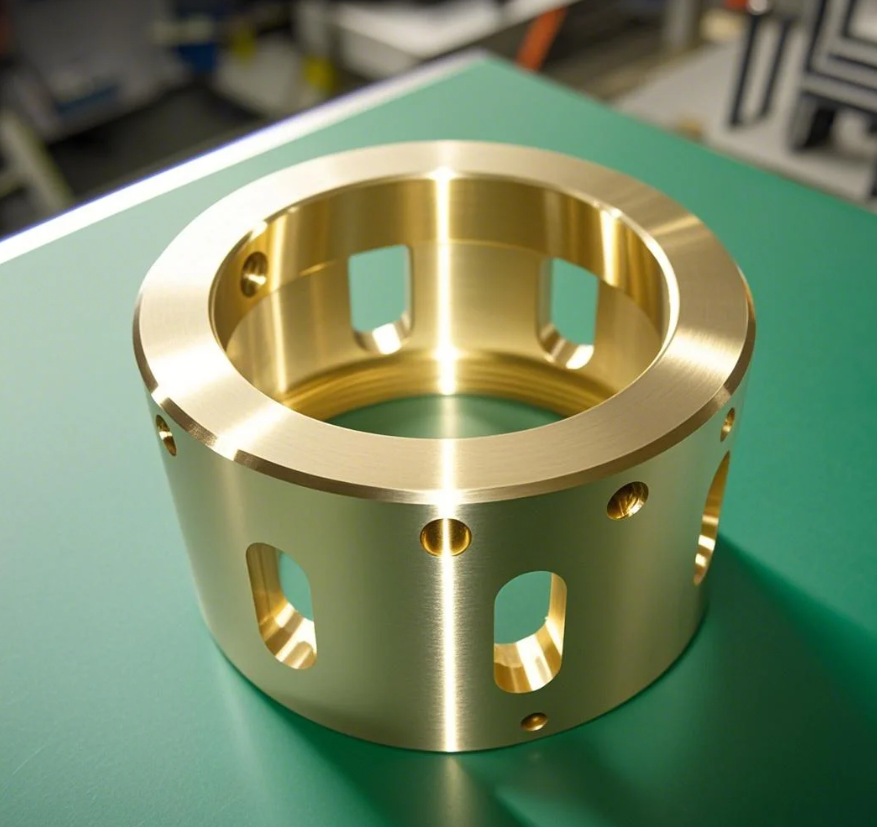

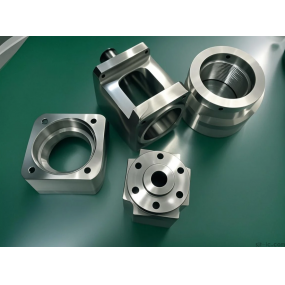

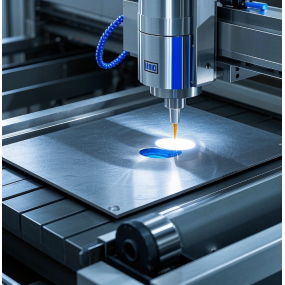

Copper's softness and high thermal conductivity demand specialized machining approaches. Our CNC precision equipment with rigid tooling and optimized cooling systems maintains ±.01mm tolerances even with copper's tendency to deform. Typical applications include:

- Electrical busbars and connectors

- Heat exchanger components

- RF waveguide parts

- Semiconductor manufacturing equipment

EMAR's Copper Machining Capabilities

Our 15,000㎡ facility features:

- 5-axis CNC mills for complex geometries

- Swiss-type lathes for precision turning

- In-house tooling department for custom solutions

- Surface roughness control to Ra .4μm

Quality Assurance Process

Every copper component undergoes:

- Material certification verification

- In-process dimensional checks

- Final CMM inspection

- Conductivity testing (when specified)

With ISO 9001 certification and 12 years of copper machining experience, EMAR ensures your components meet strict industry standards. Contact our engineering team at www.sjt-ic.com for project-specific solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque