In modern manufacturing, CNC Machining copper bars has become a critical process for industries requiring high conductivity, thermal resistance, and intricate geometries. As a leading CNC machining service provider, EMAR delivers exceptional precision and reliability for copper components across aerospace, electronics, and automotive sectors.

Why Choose CNC Machining for Copper Bars?

Copper's unique properties – excellent electrical/thermal conductivity and malleability – demand specialized machining approaches. Our CNC Machining Copper Bars services address these challenges through:

- Advanced toolpath programming to prevent material galling

- Optimized cutting parameters for burr-free edges

- Rigid machine setups minimizing vibration-induced defects

- Real-time quality monitoring systems

EMAR's Technical Capabilities

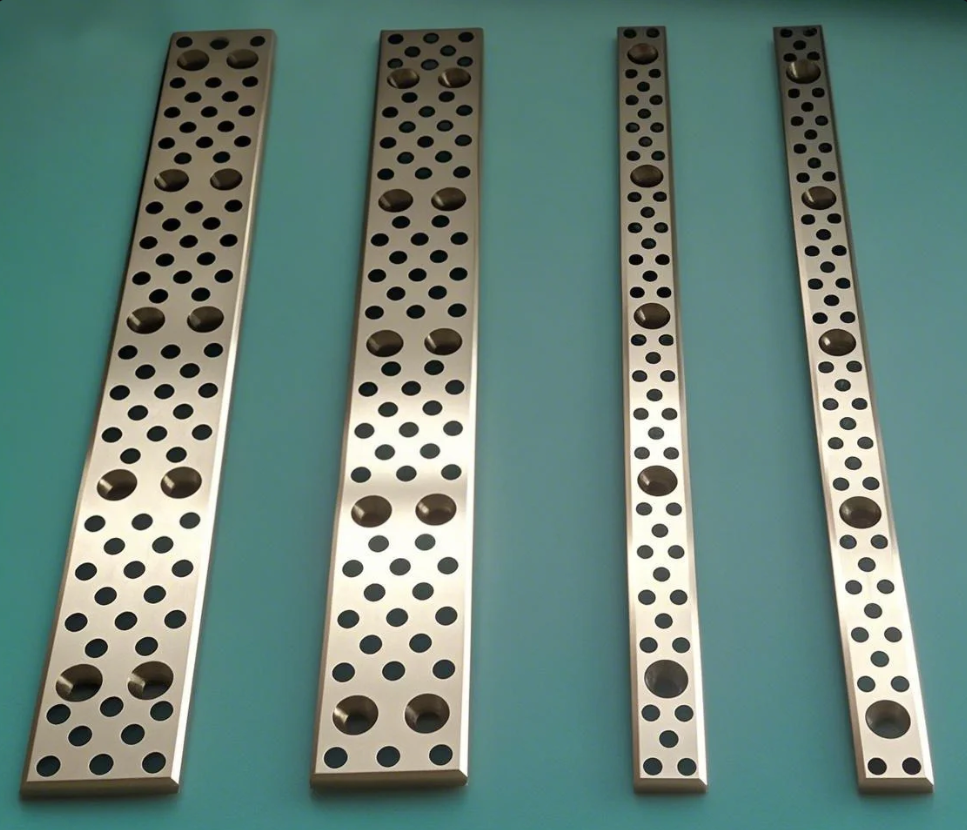

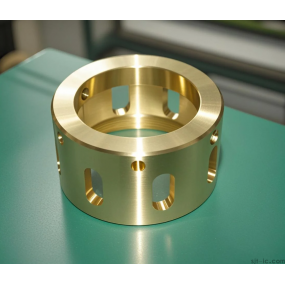

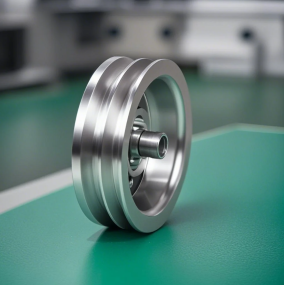

Our 5-axis CNC centers equipped with high-speed spindles (up to 30,000 RPM) ensure micron-level accuracy for complex copper bar applications:

- Tolerance: ±.01mm standard (±.005mm upon request)

- Surface finish: Ra .8μm achievable

- Maximum workpiece size: 200×800×500mm

- Materials: C11000, C10100, C14500, and other copper alloys

Industry-Specific Applications

From busbars to waveguide components, our CNC machined copper bars serve critical functions:

- Electronics: Heat sinks, connector pins, RF shielding

- Energy: Transformer windings, power distribution components

- Automotive: Charging connectors, battery terminals

With ISO 9001-certified processes and DFM support, EMAR guarantees copper parts that meet your exact specifications. Contact our engineering team for technical consultation or rapid prototyping services.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque