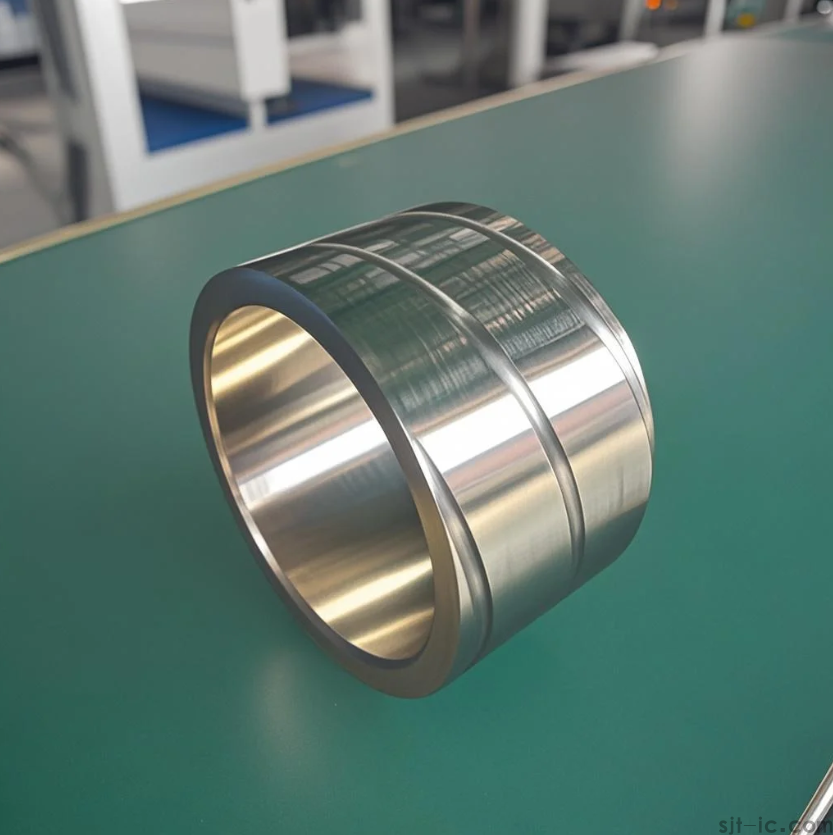

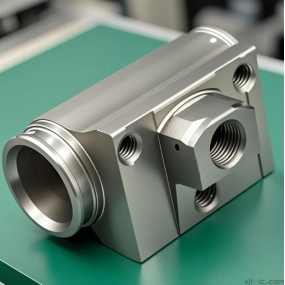

In modern manufacturing, CNC bearing machining plays a pivotal role in ensuring the performance and longevity of mechanical systems. As a specialized service provider, EMAR leverages advanced CNC technology to deliver bearings with micron-level accuracy for aerospace, automotive, and heavy machinery industries.

Why Choose CNC Machining for Bearing Production?

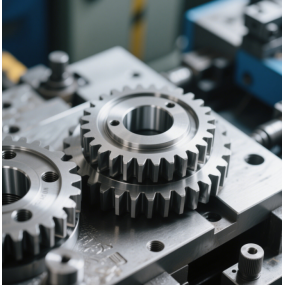

Traditional bearing manufacturing methods often struggle with complex geometries and tight tolerances. CNC bearing machining overcomes these limitations through:

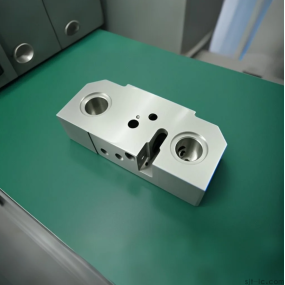

- ±.005mm dimensional accuracy

- Superior surface finishes (Ra .2-.8μm)

- Material flexibility (steel, bronze, ceramics)

- Repeatable quality for mass production

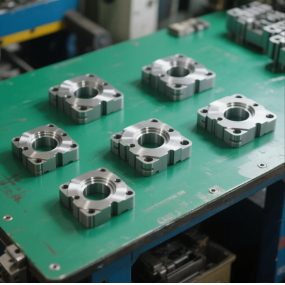

EMAR's 6-Step Bearing Machining Process

Our certified technicians follow a rigorous workflow:

- Material selection and ultrasonic testing

- Pre-machining stress relief

- Multi-axis CNC turning/milling

- Cryogenic treatment for dimensional stability

- Surface hardening (HRC 58-62)

- 100% coordinate measuring machine (CMM) inspection

Technical Advantages of Our CNC Bearing Solutions

EMAR's CNC bearing machining capabilities stand out through:

- 15+ years of bearing industry experience

- Swiss-type CNC lathes for micro-bearings (Ø3-30mm)

- In-house heat treatment facility

- ISO 9001:2015 certified quality system

- 30-day rapid prototyping service

For mission-critical applications requiring precision bearings, contact EMAR's engineering team at www.sjt-ic.com to discuss your project specifications and receive a DFM analysis within 24 hours.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque