Aluminum Profile CNC Machining What is Aluminum Profile CNC Machining?

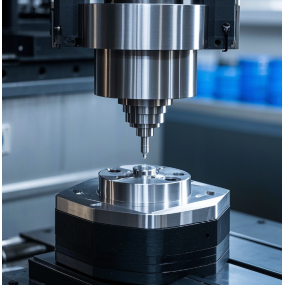

Aluminum profile CNC machining is a precision manufacturing process that involves using computer numerical control (CNC) machines to cut, drill, mill, and shape aluminum extrusions into custom components. This method ensures high accuracy, repeatability, and efficiency, making it ideal for industries such as aerospace, automotive, electronics, and construction.

At EMAR, we specialize in delivering top-quality aluminum profile CNC machining services tailored to meet stringent industry standards.

Advantages of CNC Machining for Aluminum Profiles

1. High Precision & Tight Tolerances

CNC machining guarantees dimensional accuracy, with tolerances as tight as ±.005mm, ensuring perfect fit and functionality for complex assemblies.

2. Superior Surface Finish

Our advanced CNC milling and turning processes produce smooth finishes, reducing the need for additional post-processing.

3. Cost-Effective for Prototyping & Mass Production

Whether you need a single prototype or large-scale production, CNC machining offers scalability without compromising quality.

4. Material Versatility

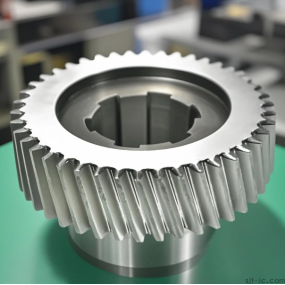

We work with various aluminum alloys (6061, 7075, etc.), optimizing strength, weight, and corrosion resistance for different applications.

EMAR’s CNC Machining Capabilities

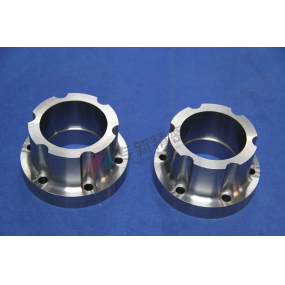

5-Axis CNC Milling – Complex geometries with multi-angle precision

CNC Turning – High-speed lathe operations for cylindrical parts

Laser Cutting & Engraving – Clean, burr-free edges

Anodizing & Powder Coating – Enhanced durability and aesthetics

Why Choose EMAR for Your Aluminum CNC Needs?

ISO 9001-certified quality management

Fast lead times with on-time delivery

Competitive pricing without hidden costs

24/7 customer support for technical consultations

For high-precision aluminum profile CNC machining, trust EMAR to deliver excellence. Contact us today for a free quote!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque