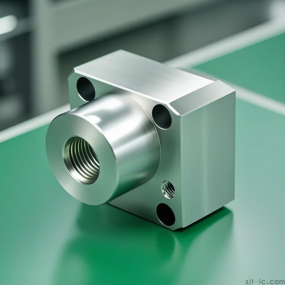

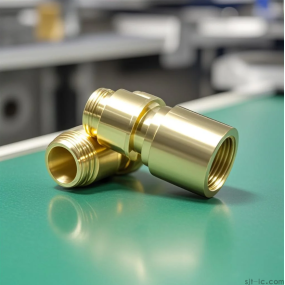

In precision manufacturing, CNC stainless steel connector machining stands as a critical process for industries demanding ultra-tight tolerances and corrosion-resistant components. EMAR Company specializes in delivering mission-critical connector solutions for aerospace, medical, and industrial applications through our advanced 5-axis CNC capabilities.

Why Choose CNC Machining for Stainless Steel Connectors?

Stainless steel's work-hardening properties require specialized CNC machining expertise. Our Swiss-type lathes and high-speed milling centers achieve surface finishes down to Ra .4μm while maintaining ±.005mm positional accuracy - essential for leak-proof fluid connectors and high-voltage electrical contacts.

Technical Specifications

We machine all stainless grades (303, 304, 316L, 17-4PH) with proprietary toolpath strategies that prevent galling. Our process includes:

- Pre-machining stress relief annealing

- High-pressure coolant threading operations

- Post-machining passivation for enhanced corrosion resistance

EMAR's Quality Assurance

Every stainless steel connector undergoes 100% dimensional verification with vision systems and CMM inspection. We maintain ISO 9001:2015 certification and provide material traceability documentation for regulated industries.

Applications

Our machined connectors serve in:

- Subsea oil/gas umbilicals

- Pharmaceutical sterile fluid systems

- Automotive fuel cell stacks

- Semiconductor vacuum chambers

With over 12,000 stainless connector production hours annually, EMAR combines German-engineered equipment with Japanese quality standards to deliver connectors that outperform cast or molded alternatives. Contact our engineering team at sjt-ic.com for DFM analysis on your next project.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque