Understanding Aluminum Parts CNC Machining

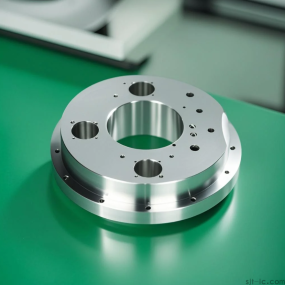

Aluminum parts CNC machining is a highly precise manufacturing process that uses computer-controlled machines to shape aluminum into custom components. At EMAR, we specialize in transforming raw aluminum materials into high-quality finished products with exceptional dimensional accuracy and surface finishes.

Our advanced CNC machining centers can handle various aluminum alloys including 6061, 7075, and 5052, each offering unique properties for different applications. The process begins with CAD designs that are converted into machine instructions, ensuring every cut, drill, and contour meets exact specifications.

Benefits of Choosing CNC Machining for Aluminum Parts

When you opt for CNC machining of aluminum parts, you gain several advantages:

- Precision: Tolerances as tight as ±.001 inches (±.025mm)

- Repeatability: Identical parts batch after batch

- Speed: Faster production compared to manual machining

- Complex geometries: Ability to create intricate designs impossible with conventional methods

- Material efficiency: Minimal waste through optimized tool paths

Our CNC Machining Capabilities for Aluminum

EMAR's state-of-the-art facility features multi-axis CNC machines capable of handling all your aluminum machining needs:

- 3-axis, 4-axis, and 5-axis milling

- CNC turning and mill-turn operations

- High-speed machining for improved surface finishes

- Secondary operations including deburring, anodizing, and powder coating

Industries We Serve

Our aluminum CNC machining services cater to diverse industries:

- Aerospace: Lightweight structural components

- Automotive: Engine parts and custom fittings

- Electronics: Heat sinks and enclosures

- Medical: Precision instruments and device components

- Industrial: Machinery parts and prototypes

Why Choose EMAR for Your Aluminum CNC Machining Needs?

EMAR stands out in the CNC machining industry with:

- 15+ years of specialized experience in aluminum machining

- ISO 9001:2015 certified quality management system

- Advanced inspection equipment including CMMs

- Competitive pricing with no compromise on quality

- Fast turnaround times without sacrificing precision

- Dedicated engineering support throughout your project

Getting Started with Your Project

Begin your aluminum CNC machining project with EMAR by:

- Submitting your CAD files (STEP, IGES, or STP formats preferred)

- Specifying your material, quantity, and surface finish requirements

- Receiving a detailed quote within 24 hours

- Approving production for fast-tracked manufacturing

Contact EMAR today to discuss how our aluminum CNC machining expertise can bring your designs to life with unmatched precision and reliability.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque