Your location:

HOME >

Service >

Numerical control machining > CNC Machining Anti-Slip Nuts

CNC Machining Anti-Slip Nuts

What Are CNC Machined Anti-Slip Nuts?CNC machined anti-slip nuts are precision-engineered fasteners designed to prevent loosening under vibration or dynamic loads. These specialize

What Are CNC Machined Anti-Slip Nuts?

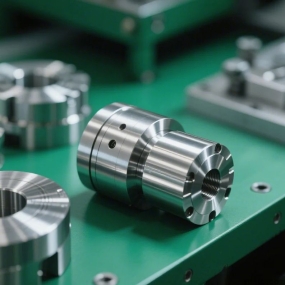

CNC machined anti-slip nuts are precision-engineered fasteners designed to prevent loosening under vibration or dynamic loads. These specialized components are manufactured using advanced CNC Machining techniques to ensure tight tolerances and superior performance in critical applications.

Key Advantages of Our CNC Anti-Slip Nuts

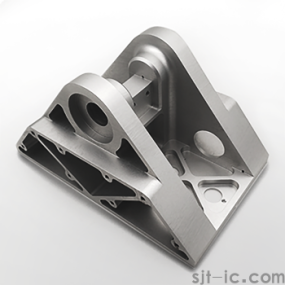

At EMAR, we produce anti-slip nuts with several competitive advantages:

- Precision tolerances (±.01mm) for perfect fit

- Customizable locking mechanisms (nylon insert, metal deformation, or flange designs)

- Material options including stainless steel, titanium, and aluminum alloys

- Surface treatments like anodizing or plating available

Our Manufacturing Process

Our CNC machining process for anti-slip nuts follows strict quality protocols:

- Material selection and inspection

- CNC turning/milling for primary shaping

- Thread cutting with precision CNC equipment

- Locking feature machining (nylon insert groove or deformation points)

- Surface treatment application

- 100% quality inspection before packaging

Why Choose EMAR for Your Anti-Slip Nut Needs?

As a professional CNC machining service provider, EMAR offers:

- 15+ years of CNC manufacturing experience

- ISO 9001 certified production facility

- Fast prototyping (3-5 day turnaround)

- Competitive pricing for bulk orders

- Technical support from our engineering team

Applications of CNC Machined Anti-Slip Nuts

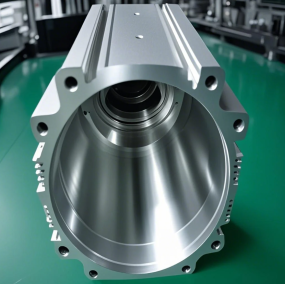

Our precision anti-slip nuts are widely used in:

- Aerospace components

- Automotive assemblies

- Industrial machinery

- Robotics and automation equipment

- Medical devices

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque