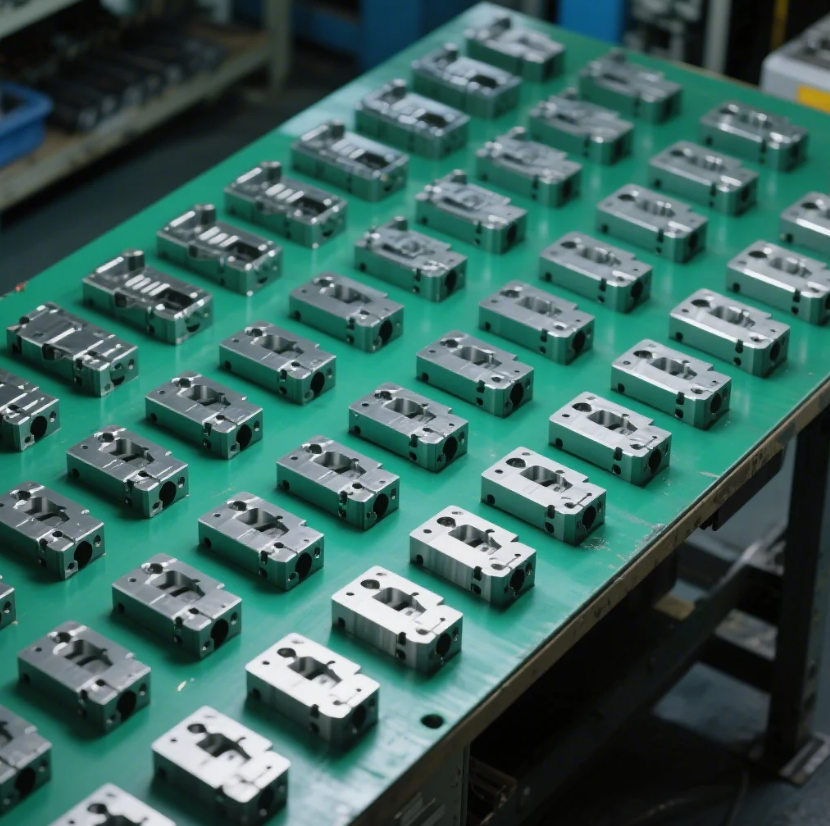

As a professional CNC Machining service provider, EMAR specializes in delivering high-precision product parts CNC machining solutions for industries ranging from aerospace to automotive. This article explores the technical process, quality control measures, and how our expertise ensures superior results.

Understanding Product Parts CNC Machining

Product parts CNC machining refers to the subtractive manufacturing process where computer-controlled machines shape raw materials (metals/plastics) into functional components with tight tolerances (typically ±.005mm). At EMAR, we utilize 5-axis CNC mills and Swiss-type lathes to handle complex geometries.

Key Stages in Our CNC Workflow

1. Design Analysis: Our engineers review CAD files to optimize manufacturability

2. Material Selection: Aluminum 6061/7075, Stainless Steel 303/304, or engineering plastics

3. Precision Machining: Multi-stage operations including milling, turning, and drilling

4. Surface Finishing: Anodizing, powder coating, or electropolishing as required

Why Choose EMAR for CNC Machined Parts?

• 40+ CNC machines with .002mm repeatability

• ISO 9001-certified quality management

• 72-hour prototyping turnaround for urgent projects

• Free DFM feedback to reduce production costs

Visit EMAR's official website to request a quote or discuss your specific CNC machining requirements with our technical team.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque