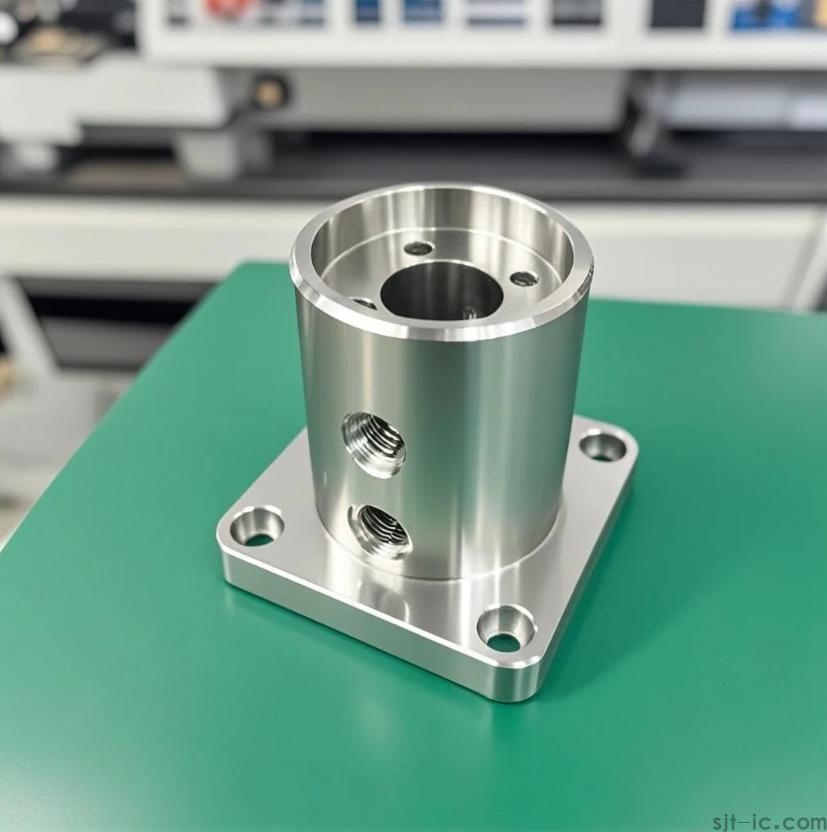

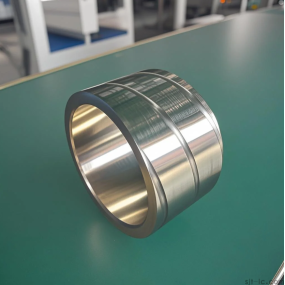

As a leading CNC Machining service provider, EMAR specializes in precision stainless steel fabrication for industries requiring exceptional durability and corrosion resistance. Our advanced machining capabilities deliver components that meet the strictest tolerances and surface finish requirements.

Understanding Stainless Steel CNC Machining

Stainless steel presents unique challenges in CNC machining due to its work-hardening properties and high strength. Our technicians employ specialized tooling and cutting parameters to overcome these challenges while maintaining dimensional accuracy and surface integrity.

Key Methods for Stainless Steel CNC Machining

1. Precision milling: Utilizing high-performance end mills with optimized coatings to reduce heat buildup and tool wear

2. CNC turning: Implementing rigid setups and proper coolant application for stable turning operations

3. Drilling and tapping: Using premium cobalt drills and form taps to create precise threaded features

4. EDM machining: For complex geometries that would be difficult with conventional cutting tools

EMAR's Technical Advantages

Our facility features state-of-the-art 5-axis CNC machines capable of handling all grades of stainless steel, from 304/316 to precipitation-hardening varieties like 17-4PH. We maintain strict quality control with CMM inspection and surface roughness measurement for every critical dimension.

Applications Across Industries

The stainless steel components we produce serve demanding applications in medical devices, aerospace, automotive, and food processing equipment. Our machining expertise ensures parts meet industry-specific standards including ISO 13485 and AS910.

Why Choose EMAR for Your Project

With over 15 years of specialized experience in stainless steel machining, we offer: technical consultation from our engineering team, DFM feedback to optimize your designs, and reliable delivery schedules backed by our vertically integrated manufacturing capabilities.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque