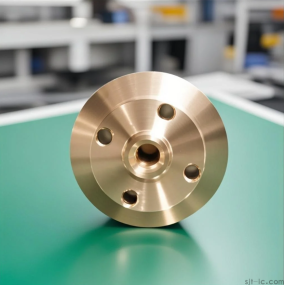

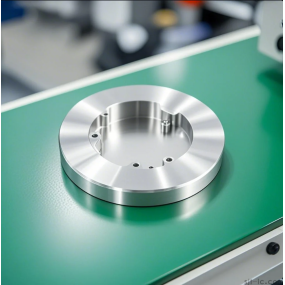

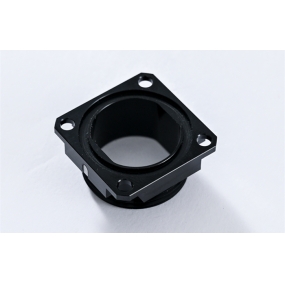

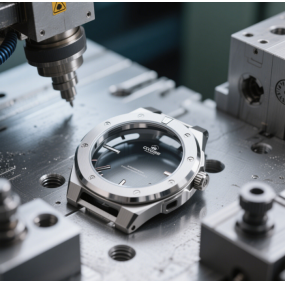

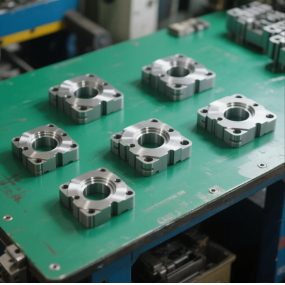

When seeking CNC machining quotation, customers should understand that pricing depends on multiple factors including material selection, part complexity, production volume, and surface finishing requirements. As EMAR Company, we provide transparent pricing models that balance precision with cost-efficiency for industrial clients.

Key Factors Affecting CNC Pricing

1. Material Costs: Aluminum, stainless steel, and titanium have different base prices

2. Machining Time: Complex geometries require longer processing

3. Tolerance Requirements: Tighter tolerances increase production costs

4. Surface Treatments: Anodizing, powder coating add value but affect pricing

EMAR's Competitive Advantages

Our CNC machining services offer:

• ISO 9001 certified production facilities

• 15+ years of aerospace and automotive industry experience

• Advanced 5-axis machining capabilities

• Just-in-time delivery options

How to Get Accurate Quotes

For precise CNC machining quotation, provide:

1. Technical drawings (STEP/IGES formats preferred)

2. Material specifications

3. Annual usage projections

4. Packaging/shipping requirements

Visit EMAR's official website to submit your RFQ or contact our engineering team for design-for-manufacturability advice that optimizes costs without compromising quality.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque