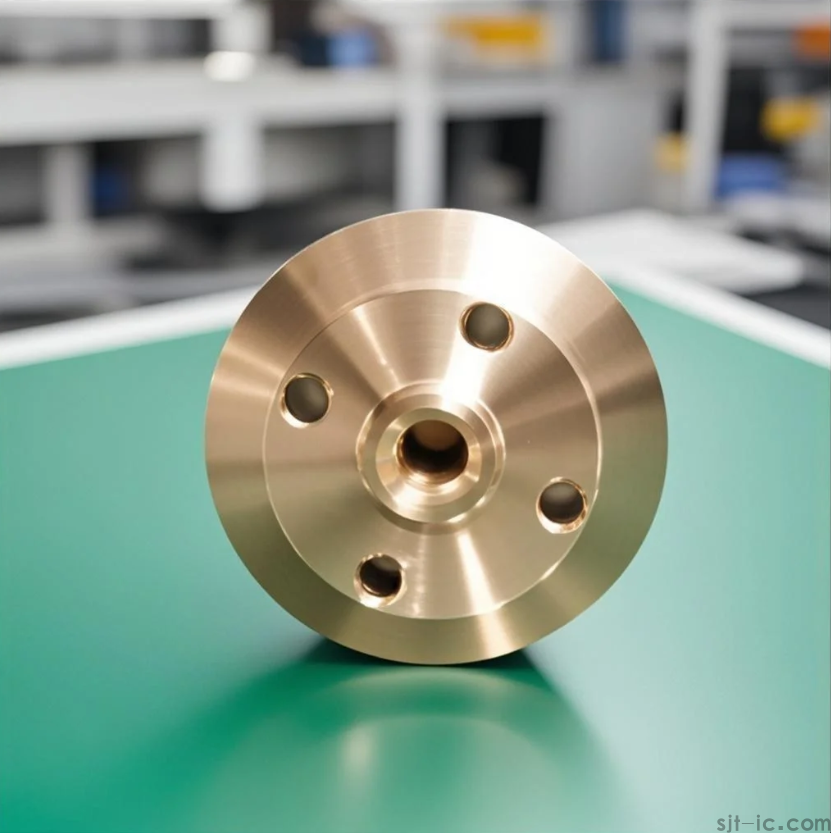

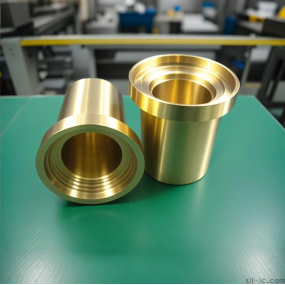

As a leading CNC bronze machining specialist, EMAR Company delivers high-precision components for critical industries. This guide explores the technical advantages and specialized processes behind bronze CNC manufacturing.

Bronze alloys offer exceptional properties for industrial components: superior corrosion resistance, excellent thermal conductivity, and natural lubricity. Our CNC bronze machining capabilities transform these material advantages into functional parts with ±.005mm tolerances.

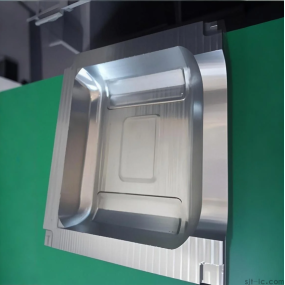

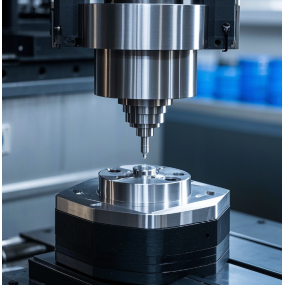

EMAR's CNC Bronze Machining Process

1. Material Selection: We work with all bronze grades (C93200, C95400, etc.) based on application requirements

2. Precision Programming: CAD/CAM optimization for complex geometries

3. Machining: Multi-axis CNC turning/milling with specialized tooling

4. Quality Control: CMM inspection and surface finish analysis

Applications of CNC Machined Bronze Components

Our CNC bronze machining serves:

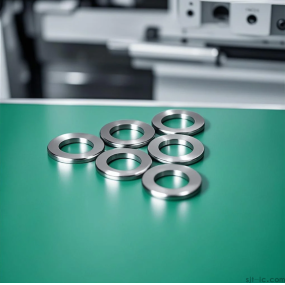

- Bushings and bearings (marine/automotive)

- Valve components (oil/gas industry)

- Electrical connectors and heat sinks

- Historical replicas and architectural hardware

EMAR's Competitive Advantages

• 15+ years of bronze machining expertise

• ISO 9001 certified quality system

• Prototype to mass production capacity

• Custom surface treatments (plating, polishing)

• Global logistics support

Visit EMAR's official website to request a free DFM analysis for your bronze components.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque