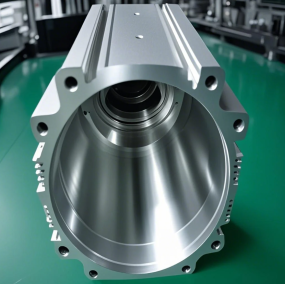

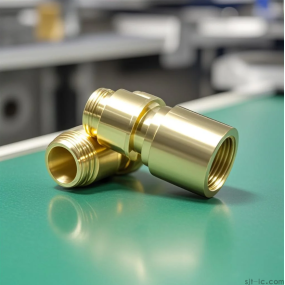

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision components for the rapidly growing new energy sector. Our expertise in CNC new energy parts machining ensures high-quality solutions for electric vehicles, solar power systems, and wind energy applications.

Why Choose CNC Machining for New Energy Components?

The new energy industry demands parts with exceptional precision, durability, and complex geometries. CNC machining offers:

- ±.005mm dimensional accuracy for critical components

- Superior surface finishes (Ra .4μm achievable)

- Material versatility (aluminum alloys, titanium, engineering plastics)

- Rapid prototyping and mass production capabilities

Key Applications in New Energy Sector

Our CNC machining services produce essential components including:

- Battery housing and cooling plates for EVs

- Precision gears and shafts for wind turbines

- Solar panel mounting brackets and connectors

- Power electronics enclosures

EMAR's Advanced Manufacturing Capabilities

Our facility features:

- 5-axis CNC machines for complex geometries

- High-speed machining centers (up to 20,000 RPM)

- Automated quality inspection systems

- ISO 9001-certified production processes

Material Selection Guide

We machine various materials suitable for new energy applications:

| Material | Properties | Typical Applications |

|---|

| 6061 Aluminum | Lightweight, corrosion-resistant | Battery enclosures |

| Grade 5 Titanium | High strength-to-weight ratio | Fuel cell components |

| PEEK | Thermal stability | Insulating parts |

Quality Assurance Process

Every part undergoes rigorous inspection:

- First-article inspection (FAI)

- In-process dimensional checks

- Final comprehensive testing (CMM, surface roughness)

- Material certification verification

Visit EMAR's official website to learn more about our CNC machining solutions for the new energy industry.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque