Precision Wheel Manufacturing Through Advanced CNC Technology

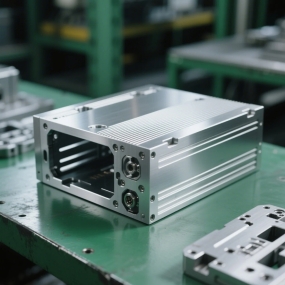

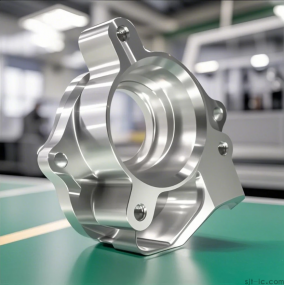

At EMAR, we specialize in CNC Machining high-performance wheels for automotive, aerospace, and industrial applications. Our state-of-the-art CNC equipment delivers unmatched precision in wheel manufacturing, ensuring perfect fitment, balance, and durability.

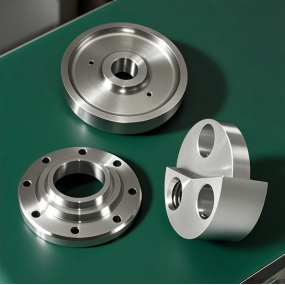

Why Choose CNC Machined Wheels?

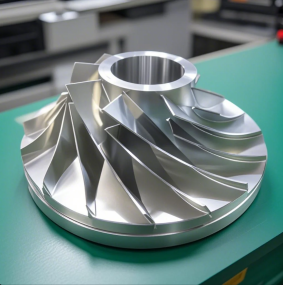

CNC technology revolutionizes wheel production by offering:

- ±.005mm dimensional accuracy for perfect hub centricity

- Superior surface finishes that reduce vibration and improve performance

- Custom designs tailored to specific vehicle requirements

- Material options including aluminum alloys, magnesium, and titanium

Our CNC Wheel Manufacturing Process

Our CNC wheel machining process follows rigorous quality standards:

- Material selection and verification

- Precision CNC turning for hub and mounting surfaces

- 5-axis CNC milling for spoke patterns and custom designs

- Surface treatment (anodizing, polishing, or powder coating)

- Final inspection and dynamic balancing

Applications of CNC Machined Wheels

Our wheels serve diverse industries:

- High-performance automotive (racing, tuning, luxury vehicles)

- Aerospace landing gear components

- Heavy-duty industrial equipment

- Motorcycle and bicycle applications

EMAR's Competitive Advantages

As a leading CNC machining manufacturer, we offer:

- 20+ years of precision machining experience

- ISO 9001 certified quality management

- Quick-turn prototyping and production services

- Comprehensive testing and quality assurance

- Competitive pricing without compromising quality

Contact EMAR today to discuss your custom wheel machining requirements. Visit our website at https://www.sjt-ic.com/ to learn more about our CNC machining capabilities.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque