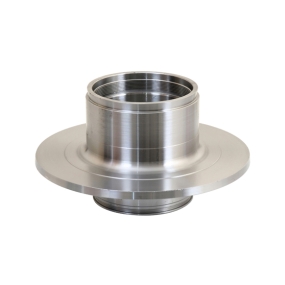

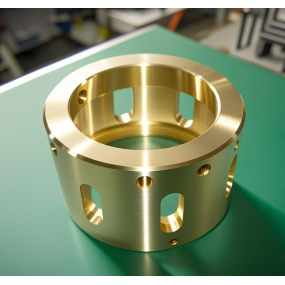

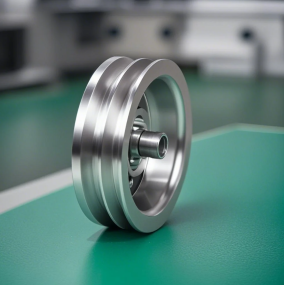

As a leading CNC Machining service provider, EMAR specializes in delivering high-precision CNC parts customization solutions tailored to diverse industrial requirements. Our advanced manufacturing capabilities ensure exceptional quality, tight tolerances, and rapid turnaround for clients across multiple sectors.

Why Choose Custom CNC Machining?

Custom CNC machining offers unparalleled advantages for precision component production. Our CNC parts customization service enables engineers to achieve complex geometries, superior surface finishes, and material versatility that traditional manufacturing cannot match. We utilize state-of-the-art 5-axis machining centers to produce prototypes and production runs with micron-level accuracy.

Our CNC Customization Process

EMAR's streamlined workflow begins with comprehensive design analysis, followed by material selection from our extensive inventory of metals and engineering plastics. Our skilled technicians then program optimized tool paths using advanced CAM software, ensuring efficient material removal and perfecting every CNC parts customization project.

Quality Assurance Commitment

Every custom CNC part undergoes rigorous inspection using coordinate measuring machines (CMM) and surface roughness testers. We maintain ISO 9001-certified quality systems to guarantee dimensional accuracy and performance consistency for all customized components.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque