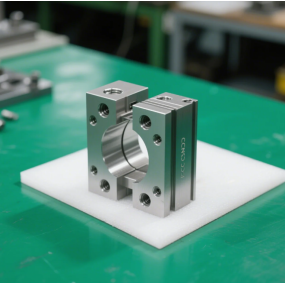

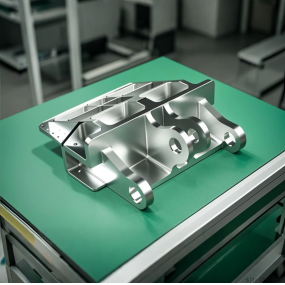

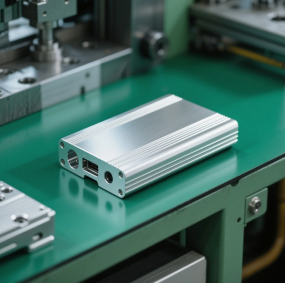

EMAR delivers aluminum profile CNC Machining solutions that combine aerospace-grade precision with industrial durability. Our ISO-certified facility specializes in complex extrusions, structural components, and high-tolerance assemblies for automotive, robotics, and automation industries.

Why Choose CNC Machining for Aluminum Profiles?

Modern aluminum profile processing demands CNC technology for three critical reasons: dimensional stability (±.01mm tolerance), efficient mass production (500+ parts/day capacity), and complex geometry capabilities (5-axis simultaneous machining). Our Haas UMC-750SS machines achieve surface finishes down to Ra .4μm.

EMAR's Technical Advantages

1. Material Expertise: 6061-T6, 7075-T6, 6082 with proprietary heat treatment

2. Specialized Tooling: Diamond-coated end mills for burr-free edges

3. Quality Systems: In-process CMM verification with automated SPC reporting

End-to-End Production Workflow

Our CNC aluminum machining process includes:

- DFM analysis within 24 hours

- Vacuum fixture design for thin-wall profiles

- Anodizing/plating ready surface treatment

- 100% dimensional inspection reports

Industry-Specific Solutions

We've delivered:

- 2,000+ LED heat sink profiles with .05mm flatness tolerance

- Medical rail systems passing ISO 13485 certification

- Automotive battery trays with IP67 sealing standards

Visit EMAR's CNC machining center to request your free design-for-manufacturing assessment today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque