As a leading CNC Machining service provider, AOOM Technologies specializes in high-volume production of precision stainless steel components for various industries. This article explores the technical considerations and advantages of our CNC batch processing solutions for stainless steel applications.

Why Choose CNC Machining for Stainless Steel Batch Production?

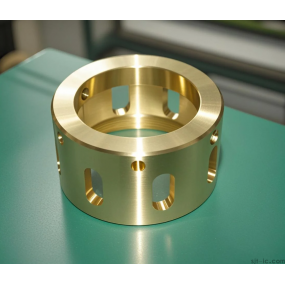

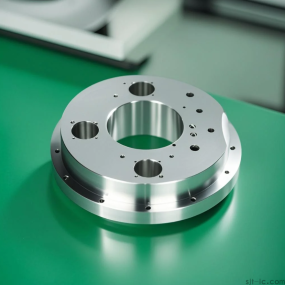

Stainless steel's exceptional corrosion resistance and mechanical properties make it ideal for critical components in aerospace, medical, and industrial applications. Our CNC batch processing capabilities ensure consistent quality across large production runs while maintaining tight tolerances (±.005mm).

Key Process Advantages at AOOM Technologies

1. Advanced Tooling Solutions: We utilize specialized carbide tools and optimized cutting parameters to overcome stainless steel's work-hardening characteristics.

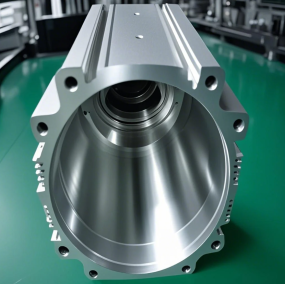

2. Automated Production: Our CNC machining centers feature robotic part handling for uninterrupted 24/7 operation.

3. Quality Assurance: In-process inspection with CMM and surface roughness testers guarantees dimensional accuracy.

Material Expertise

We machine all grades of stainless steel including 303, 304, 316, and 17-4PH, with specific techniques for each alloy's unique properties. Our engineers select optimal speeds/feeds and cooling strategies to prevent tool wear and thermal distortion.

Industries We Serve

• Medical: Surgical instruments and implant components

• Automotive: Fuel system parts and sensors

• Food Processing: Sanitary fittings and valves

• Industrial: Pump housings and hydraulic components

With ISO 9001-certified processes and DFM support, AOOM Technologies delivers cost-effective stainless steel CNC batch machining solutions from prototype to full production. Contact our engineering team today to discuss your project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque