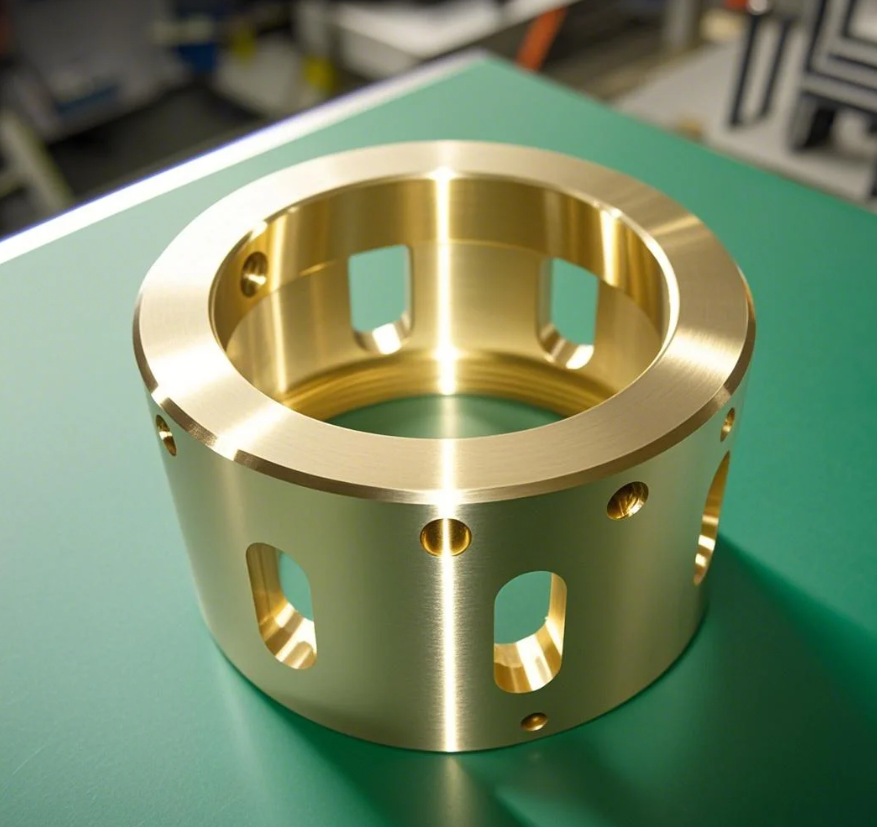

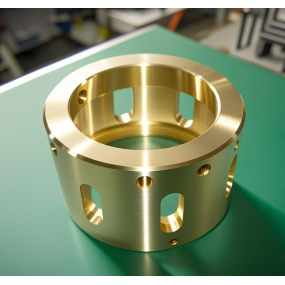

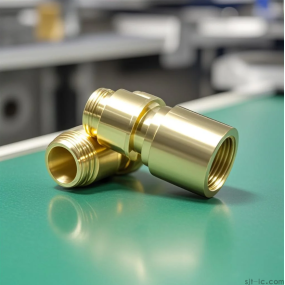

Copper is a highly versatile material widely used in industries such as electronics, automotive, and aerospace due to its excellent electrical conductivity, thermal resistance, and corrosion resistance. CNC Machining copper parts requires specialized expertise to maintain dimensional accuracy and surface finish while overcoming challenges like material softness and heat generation. At EMAR, we combine advanced CNC technology with industry-leading craftsmanship to deliver high-performance copper components tailored to your specifications.

Why Choose CNC Machining for Copper Parts?

CNC machining offers unparalleled precision for copper components, especially for complex geometries and tight tolerances (±.01mm). Our 5-axis CNC mills and lathes ensure efficient material removal while minimizing tool wear. Key advantages include:

-

Superior surface finishes (up to Ra .4μm) for electrical contacts

-

Repeatable accuracy for high-volume production

-

Flexibility for prototypes and custom designs

EMAR's Copper CNC Machining Capabilities

Our facility features state-of-the-art CNC equipment specifically configured for non-ferrous metals:

-

High-speed machining centers (up to 30,000 RPM) to prevent material buildup

-

Coolant systems optimized for copper's thermal properties

-

In-process quality control with CMM measurement

Applications of Precision Copper Components

We manufacture CNC machined copper parts for critical applications including:

-

Electrical busbars and connectors

-

Heat exchanger components

-

RF shielding enclosures

-

Semiconductor manufacturing equipment

With ISO 9001-certified processes and DFM support, EMAR delivers copper parts that meet MIL-STD and ASTM standards. Contact our engineering team at www.sjt-ic.com for technical consultation and instant quoting on your copper machining project.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque