In the realm of precision manufacturing, CNC mold machining production stands as a cornerstone for industries requiring high-accuracy components. EMAR, as a specialized CNC Machining service provider, leverages advanced technology and stringent quality control to deliver exceptional mold solutions tailored to your specifications.

What is CNC Mold Machining?

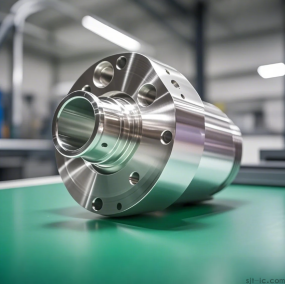

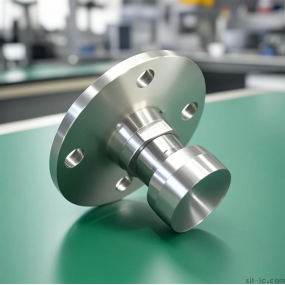

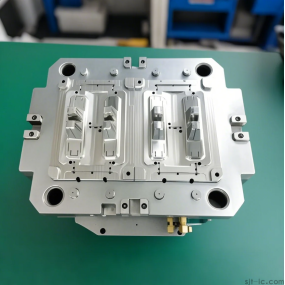

CNC mold machining refers to the process of using computer numerical control (CNC) systems to fabricate molds with intricate geometries and tight tolerances. This method ensures repeatability, efficiency, and superior surface finishes, making it ideal for injection molding, die casting, and stamping applications.

Key Advantages of Our CNC Mold Production

1. Precision Engineering: Our 5-axis CNC machines achieve micron-level accuracy for complex mold cavities.

2. Material Versatility: We work with tool steels, aluminum alloys, and engineered plastics.

3. Rapid Prototyping: Accelerate your product development with our quick-turn mold fabrication.

4. Surface Treatment: Optional polishing, texturing, or coating services enhance mold durability.

EMAR's Technical Capabilities

Our facility features:

- High-speed CNC milling centers (up to 15,000 RPM)

- EDM (Electrical Discharge Machining) for delicate features

- CMM inspection equipment for quality verification

- CAD/CAM software integration for seamless design-to-production workflows

For CNC mold machining production that combines technical excellence with competitive pricing, contact EMAR to discuss your project requirements. Our team of certified machinists and engineers is ready to transform your designs into high-performance molds.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque