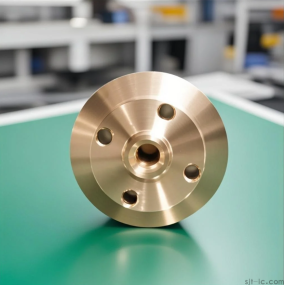

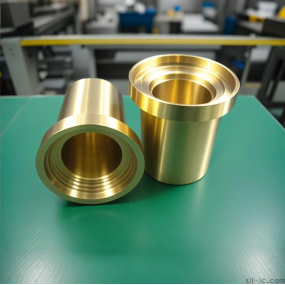

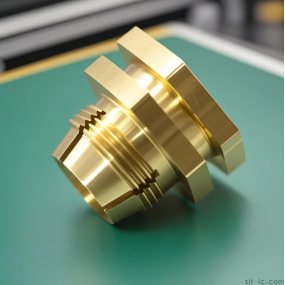

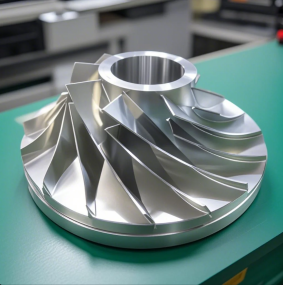

Selecting a reliable CNC parts manufacturer is critical for industries demanding high precision, durability, and cost-efficiency. EMAR, a professional CNC Machining service provider, offers insights into key considerations to ensure optimal results for your projects.

1. Technical Capabilities and Equipment

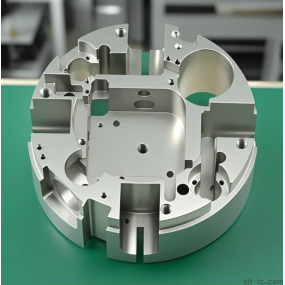

A top-tier CNC parts manufacturer must possess advanced multi-axis CNC machines, CAD/CAM software, and metrology tools. EMAR’s facility houses state-of-the-art equipment to handle complex geometries, tight tolerances (±.005mm), and diverse materials like aerospace alloys and medical-grade plastics.

2. Quality Assurance Protocols

Certifications (ISO 9001, AS910) and rigorous inspection processes (CMM, surface roughness testing) are non-negotiable. EMAR implements a 100% quality check policy, ensuring every component meets industry standards and client specifications.

3. Scalability and Lead Time

From prototyping to mass production, a manufacturer’s ability to scale while maintaining deadlines is vital. EMAR’s agile production lines and just-in-time inventory reduce lead times by 30% compared to industry averages.

4. Cost-Effectiveness Without Compromise

Competitive pricing should align with value. EMAR optimizes machining strategies (e.g., DFM analysis) to minimize waste and lower per-unit costs, offering transparent quotes with no hidden fees.

Why Partner with EMAR?

With 15+ years in precision CNC machining, EMAR serves automotive, robotics, and semiconductor sectors globally. Our end-to-end solutions—from design support to logistics—ensure seamless collaboration. Visit www.sjt-ic.com to request a quote or discuss your project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque