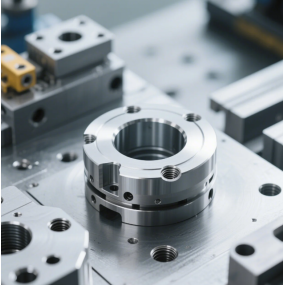

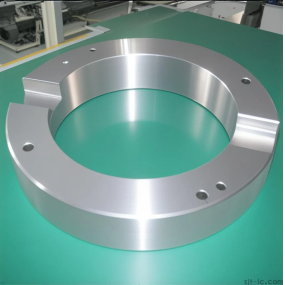

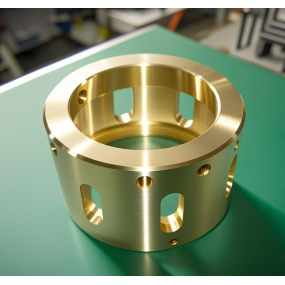

As a leading CNC titanium steel machining specialist, EMAR Technology provides precision manufacturing solutions for aerospace, medical, and industrial applications. Our ISO-certified facility combines advanced machinery with metallurgical expertise to deliver exceptional results.

Why Choose CNC for Titanium Steel?

Titanium steel alloys demand specialized CNC Machining techniques due to their unique properties. Our process addresses three critical challenges:

-

High tool wear from titanium's abrasiveness

-

Workpiece deformation risks

-

Surface integrity requirements

Our Precision Machining Workflow

1. Material Analysis: Spectrometer verification of alloy composition

2. Toolpath Optimization: CAM programming with chip load calculations

3. Controlled Machining: High-pressure coolant application

4. Quality Assurance: CMM inspection with ±.005mm tolerance

EMAR's Technical Advantages

Our CNC titanium steel capabilities include:

- 5-axis simultaneous machining centers

- Cryogenic machining options for stress reduction

- Anodizing and passivation post-processing

Visit sjt-ic.com to request your free DFM analysis today. Our engineering team provides technical consultation throughout your project lifecycle.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque