As a leading CNC connector product processing specialist, EMAR Company delivers precision-engineered solutions for industries requiring high-performance electrical and mechanical connections. Our advanced CNC Machining capabilities ensure dimensional accuracy down to ±.005mm for critical connector components.

Why Choose CNC Machining for Connector Products?

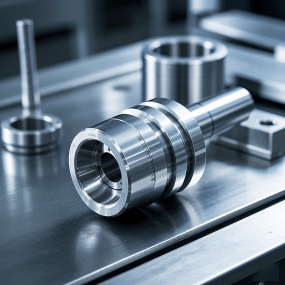

CNC connector product processing offers unparalleled advantages over conventional manufacturing methods. Our 5-axis CNC machines produce complex geometries in brass, copper alloys, and engineering plastics with perfect repeatability. The automated process eliminates human error while achieving surface finishes up to Ra .4μm - essential for reliable electrical contacts.

EMAR's CNC Connector Manufacturing Process

Our certified production workflow includes:

1. Material selection (certified C26000 brass, phosphor bronze, etc.)

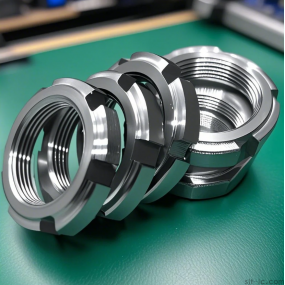

2. Precision CNC turning/milling of contact pins and housings

3. Thread cutting and micro-drilling (up to .3mm diameter)

4. Deburring and surface treatment (gold/nickel plating available)

5. 100% automated dimensional inspection

Industry-Specific Solutions

We specialize in CNC connector product processing for:

• Automotive connectors (sealed types for EV applications)

• Industrial circular connectors (M8/M12/M23 standards)

• High-speed data connectors (impedance-controlled designs)

• Custom military-spec connectors (MIL-DTL-38999 series)

With ISO 9001:2015 certification and 15+ years of connector manufacturing experience, EMAR guarantees traceable quality from prototype to mass production. Request your free DFM analysis today at www.sjt-ic.com.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque