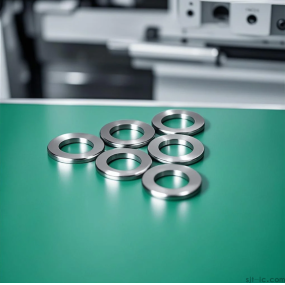

In modern manufacturing, Custom CNC Machining for Metal Parts (CNC metal parts customization) has become the cornerstone of precision engineering. As a leading provider at EMAR, we specialize in delivering tailored CNC machining solutions for diverse industrial applications.

What is CNC Metal Parts Customization?

Custom CNC Machining for Metal Parts refers to the process of using computer-controlled machines to manufacture metal components according to exact client specifications. This service covers everything from prototyping to mass production of brass, aluminum, steel, and alloy parts with tolerances as tight as ±.005mm.

Key Advantages of Our Service

1. Precision Engineering: Our 5-axis CNC machines achieve surface finishes up to Ra .2μm

2. Material Versatility: Capable of processing over 50 metal alloys including titanium and magnesium

3. Rapid Turnaround: 3-5 day standard lead time with 24/7 production capacity

Industry-Specific Applications

We serve critical sectors requiring Custom CNC Machining for Metal Parts:

- Automotive: Engine components, transmission parts

- Electronics: Heat sinks, connector housings

- Medical: Surgical instruments, implantable devices

- Aerospace: Turbine blades, structural components

Why Choose EMAR for Your Project?

With 15+ years in CNC machining, we offer:

- ISO 9001 & IATF 16949 certified production

- DFM analysis with proprietary optimization software

- Complete post-processing (anodizing, plating, painting)

- 100% quality inspection with CMM equipment

Visit our website at https://www.sjt-ic.com/ to request a free project evaluation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque