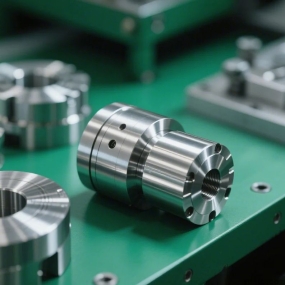

As a professional non-standard CNC parts processing manufacturer, EMAR specializes in delivering high-precision, customized machining solutions for industries requiring complex and unique components. Our advanced CNC technology ensures accuracy, efficiency, and reliability for every project.

What is Non-Standard CNC Parts Processing?

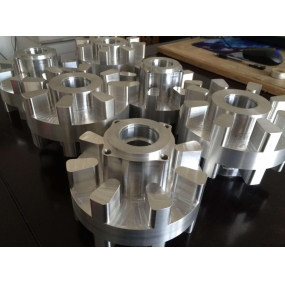

Non-standard CNC parts processing refers to the manufacturing of components that deviate from standard specifications, often requiring custom designs, tight tolerances, or specialized materials. Unlike mass-produced parts, these are tailored to meet specific client needs, making the role of a skilled CNC Machining manufacturer critical.

Key Advantages of Choosing EMAR

1. Precision Engineering: Our state-of-the-art CNC machines achieve tolerances as tight as ±.01mm.

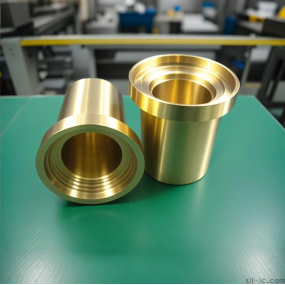

2. Material Versatility: We work with metals (aluminum, titanium, stainless steel), plastics, and composites.

3. End-to-End Service: From design support to post-processing (e.g., anodizing, plating), we streamline production.

4. Industry-Specific Solutions: Expertise in aerospace, automotive, medical devices, and robotics.

Applications of Non-Standard CNC Parts

Custom CNC components are vital in:

- Prototyping: Rapid iteration of unique designs.

- Low-Volume Production: Cost-effective for niche applications.

- Complex Geometries: Features like internal channels or multi-axis contours.

Why Partner with EMAR?

With ISO 9001 certification and a commitment to lean manufacturing, EMAR guarantees:

- On-Time Delivery: Agile production schedules.

- Competitive Pricing: Optimized processes reduce waste.

- Technical Support: 24/7 engineering assistance for non-standard CNC parts challenges.

Explore our capabilities at EMAR’s official website and request a quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque