In modern manufacturing, CNC hard metal machining represents one of the most challenging yet essential processes for producing high-performance components. As an industry leader, EMAR Company specializes in delivering exceptional precision for hard metal applications through our advanced CNC capabilities.

Understanding CNC Hard Metal Machining

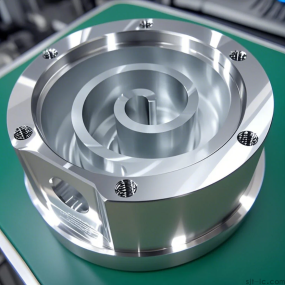

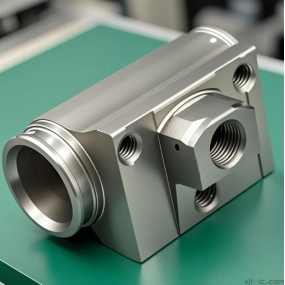

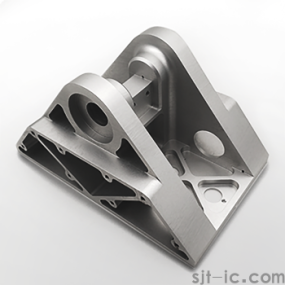

CNC hard metal machining refers to the computer-controlled cutting, milling, and shaping of materials with hardness exceeding 45 HRC, including hardened steels, titanium alloys, and superalloys. This process requires specialized tooling, rigid machine structures, and optimized cutting parameters to maintain dimensional accuracy while preventing tool wear.

Key Challenges in Hard Metal Machining

Working with hard metals presents unique obstacles that EMAR's technicians expertly overcome:

- Extreme tool wear requiring advanced carbide or diamond-coated cutters

- High cutting forces demanding rigid machine setups

- Precision thermal management to prevent workpiece distortion

- Surface integrity maintenance for critical applications

EMAR's Technical Advantages

Our CNC hard metal machining solutions stand out through:

- 5-axis machining centers with high-pressure coolant systems

- Advanced toolpath programming for optimal material removal

- In-process monitoring systems ensuring consistent quality

- Surface finishing capabilities down to Ra .2μm

Applications Across Industries

EMAR's hard metal machining serves demanding sectors including aerospace (turbine components), medical (surgical instruments), automotive (transmission parts), and energy (drilling equipment). Our technical team works closely with clients to develop customized solutions for each application's specific requirements.

Quality Assurance Protocol

Every hard metal component undergoes rigorous inspection using coordinate measuring machines (CMMs), surface roughness testers, and hardness testers to guarantee compliance with the strictest industry standards and customer specifications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque