As a professional CNC copper parts machining service provider, EMAR Company specializes in delivering high-precision custom solutions for industries requiring superior electrical/thermal conductivity and corrosion resistance.

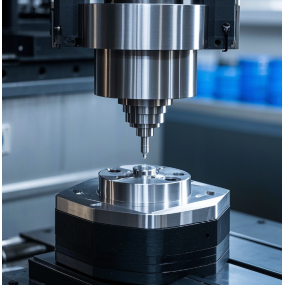

Why Choose CNC Machining for Copper Parts?

Copper's unique properties demand specialized CNC machining techniques. Our computer-controlled processes ensure ±.01mm tolerances while preventing material deformation through optimized tool paths and cooling strategies.

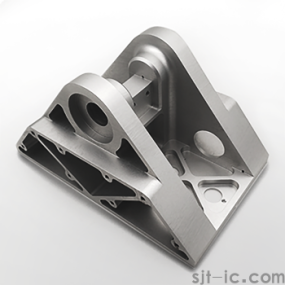

Custom Machining Capabilities

We offer full-axis machining for complex geometries including:

- Electrical connectors and busbars

- Heat exchanger components

- Waveguide and RF components

- Decorative architectural elements

All parts undergo strict quality verification per ISO 9001 standards.

Material Selection Guidance

Our engineers help select optimal copper alloys:C11000 (ETP Copper), C14500 (Tellurium Copper), or C17200 (Beryllium Copper) based on your conductivity, strength, and machinability requirements.

Surface Treatment Options

Complete post-processing services include:

- Electroplating (nickel/silver/gold)

- Passivation and anti-tarnish coatings

- Polishing to Ra .2μm mirror finishes

Visit EMAR's official website to request a free DFM analysis for your copper component project. Our 15+ years of CNC expertise ensures manufacturability and cost efficiency from prototype to mass production.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque