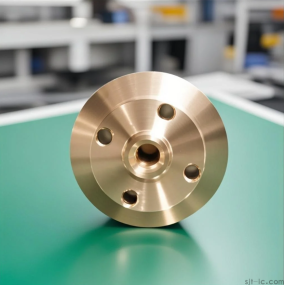

Understanding CNC Small Aluminum Parts Machining

CNC small aluminum parts machining is a specialized manufacturing process that combines computer numerical control technology with aluminum's excellent machinability to produce high-precision components. At EMAR, we specialize in creating intricate aluminum parts with tight tolerances, perfect for industries requiring lightweight yet durable components.

Why Choose CNC for Small Aluminum Components?

Aluminum is one of the most machinable metals, making it ideal for CNC Machining applications. When producing small parts, CNC technology offers several advantages:

- Exceptional precision (tolerances up to ±.005mm)

- Consistent quality across large production runs

- Complex geometries achievable in single setups

- Superior surface finishes without secondary operations

- Cost-effective for both prototypes and mass production

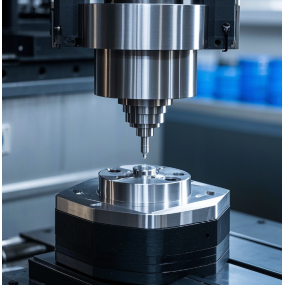

Our CNC Machining Process for Small Aluminum Parts

EMAR follows a meticulous process to ensure the highest quality small aluminum components:

- Material Selection: Choosing the right aluminum alloy (6061, 7075, etc.) for your application

- CAD/CAM Programming: Creating optimized toolpaths for maximum efficiency

- Precision Machining: Using state-of-the-art CNC mills and lathes

- Quality Inspection: Implementing CMM and other metrology tools

- Surface Treatment: Applying anodizing, polishing, or other finishes as required

Applications of CNC Machined Small Aluminum Parts

Our precision-machined aluminum components serve various industries:

- Aerospace: Lightweight brackets and fittings

- Electronics: Heat sinks and enclosures

- Medical: Surgical instrument components

- Automotive: Engine and transmission parts

- Robotics: Precision movement components

Why Partner with EMAR for Your CNC Needs?

EMAR stands out in the CNC machining industry with:

- 15+ years of specialized experience in aluminum machining

- ISO 9001 certified quality management system

- Advanced 5-axis CNC capabilities for complex geometries

- Competitive pricing with fast turnaround times

- Comprehensive engineering support from design to delivery

For your next project requiring precision CNC small aluminum parts machining, contact EMAR at www.sjt-ic.com to discuss how we can meet your specific requirements with our technical expertise and manufacturing excellence.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque