As a leading CNC tungsten steel product machining specialist, EMAR delivers unmatched precision for industries requiring extreme hardness and thermal stability. This guide explores our technical capabilities and why tungsten carbide machining stands apart in precision manufacturing.

Why Choose CNC Machining for Tungsten Steel Products?

Tungsten carbide (WC) demands specialized CNC machining due to its exceptional hardness (90-92 HRA). Our 5-axis CNC centers equipped with PCD tools maintain ±.005mm tolerances while overcoming tungsten's brittleness challenges through:

-

Optimized cutting parameters (50-150 m/min cutting speed)

-

High-pressure coolant systems

-

Vibration-dampened machining strategies

EMAR's Tungsten Machining Process Flow

Our certified CNC tungsten steel product machining workflow ensures dimensional stability:

-

Material certification (ISO 9001 compliant)

-

Pre-machining stress relief annealing

-

Multi-stage roughing with ceramic inserts

-

Semi-finishing with CBN tools

-

Final precision grinding (when required)

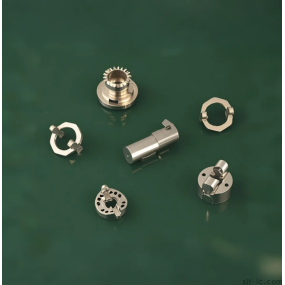

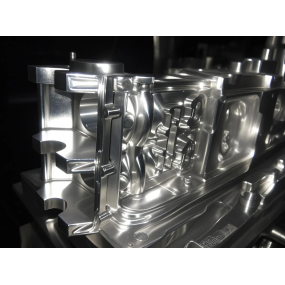

Applications of Machined Tungsten Components

From medical radiation shields to semiconductor wafer chucks, our machined tungsten products serve:

-

Mold & die industry (core pins, ejector sleeves)

-

Oil/gas (valve components, drill bits)

-

Aerospace (counterweights, turbine components)

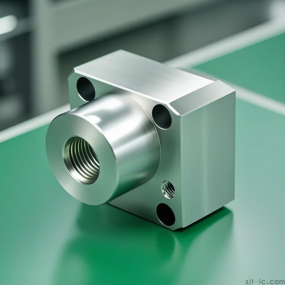

EMAR's Technical Advantages

Our Shenzhen facility features:

-

10+ dedicated tungsten machining centers

-

In-house CMM inspection (Zeiss CONTURA)

-

EDM capabilities for complex geometries

-

Surface finishes to Ra .2μm

Request a quote for your CNC tungsten steel product machining project at www.sjt-ic.com, where we combine German-engineered equipment with 15+ years of hard metal machining expertise.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque