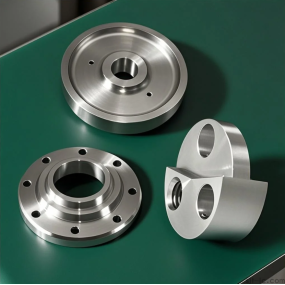

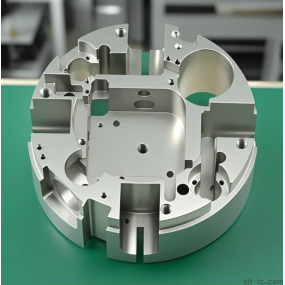

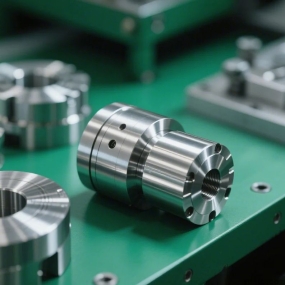

As a leading CNC batch product processing specialist, EMAR Technology delivers high-volume precision manufacturing solutions for industries requiring consistent quality and tight tolerances.

What Is CNC Batch Production?

CNC batch product processing refers to the manufacturing of medium-to-large quantities (typically 50-10,000 units) of identical components using computer-controlled machining systems. This approach combines the efficiency of mass production with the precision of CNC technology.

Key Advantages of Our Batch Processing

1. Cost Efficiency: Reduced per-unit costs through optimized tool paths and material utilization

2. Consistent Quality: ±.005mm tolerance maintained across entire batches

3. Material Versatility: Aluminum, steel, titanium, plastics, and engineered composites

EMAR's Batch Processing Workflow

Our certified CNC batch product processing follows a rigorous 6-stage protocol:

1. DFM analysis

2. Fixture design optimization

3. Tooling presetting

4. First-article inspection

5. Automated production monitoring

6. Final QC with CMM verification

Industries We Serve

• Automotive components

• Aerospace fasteners

• Medical device parts

• Electronics enclosures

• Industrial equipment spares

With ISO 9001:2015 certified facilities and 12+ years of CNC Machining expertise, EMAR ensures your batch orders meet the highest industry standards while achieving 15-30% cost savings versus competitors.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque