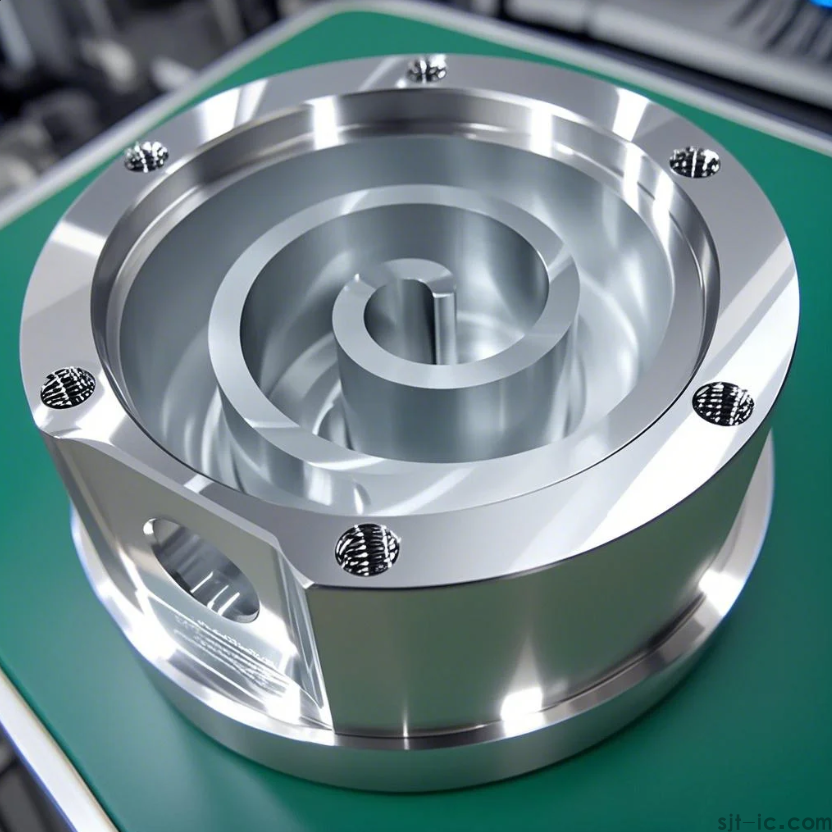

Aluminum CNC machining is a precise manufacturing process that uses computer numerical control (CNC) technology to shape aluminum parts with high accuracy. As one of the most commonly machined metals, aluminum offers excellent machinability, strength-to-weight ratio, and corrosion resistance, making it ideal for various industries including aerospace, automotive, and electronics.

The Aluminum CNC Machining Process Flow

Our CNC machining process for aluminum involves several critical steps:

1. Material Selection: Choosing the right aluminum alloy (6061, 7075, etc.) based on application requirements

2. CAD Design: Creating or converting 3D models into machine-readable formats

3. CAM Programming: Generating toolpaths and selecting appropriate cutting tools

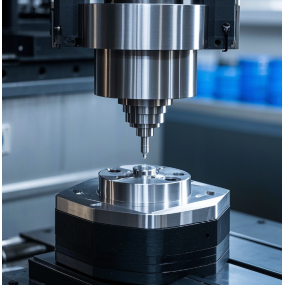

4. Machine Setup: Securing the aluminum workpiece and installing required tools

5. Precision Machining: Executing milling, turning, or drilling operations

6. Quality Inspection: Verifying dimensions and surface finish

7. Post-processing: Applying treatments like anodizing or powder coating

Why Choose EMAR for Your Aluminum CNC Machining Needs?

EMAR stands out in the CNC machining industry with our:

- State-of-the-art CNC machines with multi-axis capabilities

- Experienced technicians with deep material knowledge

- Strict quality control measures meeting ISO standards

- Competitive pricing and fast turnaround times

- Custom solutions for both prototyping and mass production

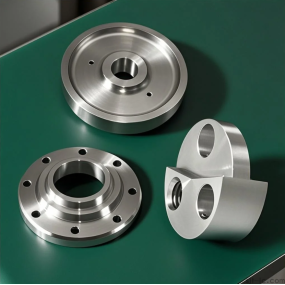

Applications of CNC Machined Aluminum Parts

Our precision-machined aluminum components serve diverse applications including:

• Aerospace structural components

• Automotive engine parts

• Electronic enclosures and heat sinks

• Medical device components

• Robotics and automation systems

Contact EMAR for Your CNC Machining Projects

With advanced capabilities in aluminum machining, EMAR is your trusted partner for high-quality CNC components. Visit our website at https://www.sjt-ic.com/ to learn more about our services or request a quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque