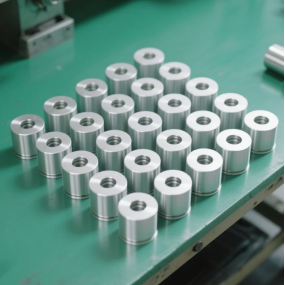

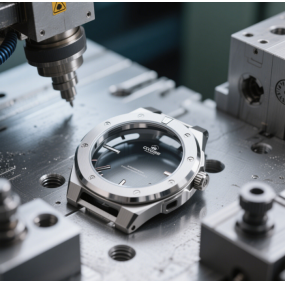

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision aircraft components that meet stringent aerospace standards. This article explores the technical aspects and quality control measures behind our aircraft parts CNC machining capabilities.

Why CNC Machining is Critical for Aircraft Components

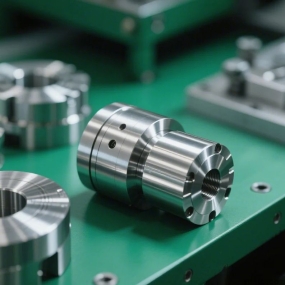

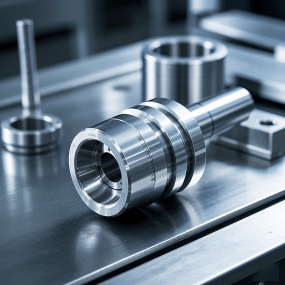

Aerospace applications demand extreme precision and reliability. Our 5-axis CNC machines achieve tolerances within ±.0005 inches (.0127mm), ensuring perfect fit and function for flight-critical parts. We machine aluminum alloys, titanium, and high-temperature composites used in structural components, landing gear, and engine parts.

EMAR's Aerospace Machining Capabilities

Our facility features:

15 advanced CNC machining centers with automatic tool changers

In-process inspection using CMM and laser scanning

NADCAP-certified quality management system

Material traceability for all aerospace components

Quality Assurance Process

Every aircraft part undergoes:

First-article inspection (FAI) per AS9102 standards

Dimensional verification with 3D scanning

Surface finish analysis

Final certification including material test reports

Why Choose EMAR for Your Aerospace Projects

With 12 years of experience serving aerospace manufacturers, we offer:

Prototype to production volume capabilities

ITAR-compliant data security

30% faster lead times than industry average

Dedicated engineering support

Contact EMAR today to discuss your aircraft component requirements at www.sjt-ic.com. Our team is ready to provide technical consultation and manufacturing solutions for your most challenging aerospace applications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque