As a leading CNC Machining service provider, EMAR specializes in manufacturing precision components for electric bicycles. Our advanced machining capabilities ensure high-quality parts that meet the demanding requirements of modern e-bike manufacturers.

Why Choose CNC Machining for E-Bike Components?

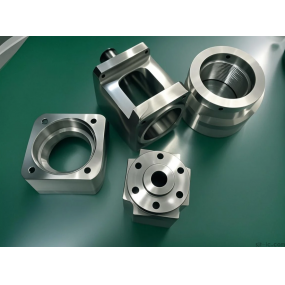

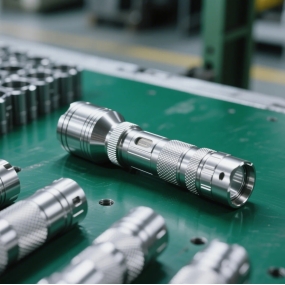

Electric bicycles require lightweight yet durable parts with complex geometries. CNC machining offers unparalleled precision for producing critical components like motor housings, brake system parts, and structural elements. Our 5-axis CNC machines can create intricate designs with tolerances as tight as ±.005mm.

Our E-Bike CNC Machining Capabilities

EMAR's facility features state-of-the-art CNC equipment specifically configured for electric bicycle parts production. We work with various materials including aluminum alloys, titanium, and engineering plastics to deliver optimal strength-to-weight ratios for your e-bike applications.

Quality Assurance Process

Every component undergoes rigorous inspection using CMM machines and surface roughness testers. Our ISO 9001-certified quality system ensures consistent performance of your electric bicycle parts throughout their lifecycle.

Advantages of Partnering with EMAR

1. DFM (Design for Manufacturing) support to optimize your part designs

2. Rapid prototyping to accelerate your product development cycle

3. Flexible production volumes from prototypes to mass production

4. Competitive pricing with short lead times

Contact EMAR today to discuss your electric bicycle component requirements. Visit our website at https://www.sjt-ic.com/ to learn more about our comprehensive CNC machining services.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque