As a professional CNC gear machining service provider, EMAR understands that pricing is a critical concern for procurement managers and engineers. This article breaks down the key factors affecting costs and how our solutions deliver competitive value.

What Determines CNC Gear Machining Prices?

The cost of CNC gear machining depends on:

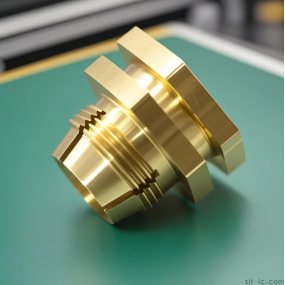

Material selection: Aerospace aluminum vs. hardened steel impacts tool wear and machining time

Gear complexity: Helical/bevel gears require multi-axis machining (higher cost than spur gears)

Tolerances: AGMA Class 10+ precision demands specialized equipment

Order volume: Batch production reduces per-unit cost through optimized tool paths

EMAR's Cost Optimization Approach

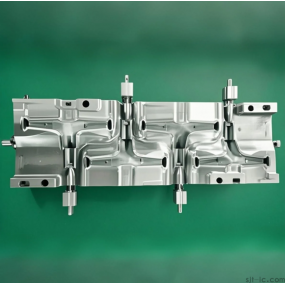

Our CNC Machining center implements:

Advanced CAM programming to minimize material waste

In-house tool grinding to extend cutter lifespan

Multi-pallet systems for uninterrupted production

Transparent Pricing Structure

Unlike vendors with hidden fees, EMAR provides:

DFM analysis reports with cost breakdowns

Volume-based discount tiers

Ex-works/FOB price options

Request a custom quote with your gear specifications (module, pressure angle, tooth count) for precise pricing. Our engineers will suggest the most cost-effective manufacturing strategy without compromising quality.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque