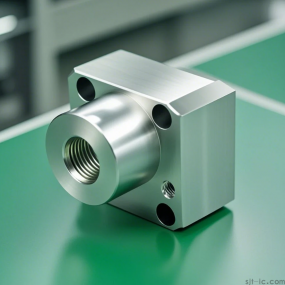

In today's competitive manufacturing landscape, high-volume CNC parts machining demands a perfect balance of precision, cost-effectiveness, and reliable turnaround. As a trusted CNC Machining service provider, EMAR specializes in delivering complex components at scale while maintaining uncompromising quality standards.

What Is High-Volume CNC Parts Machining?

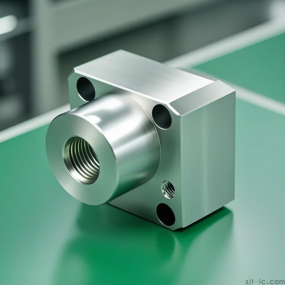

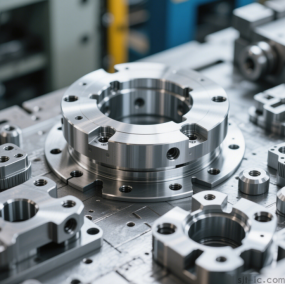

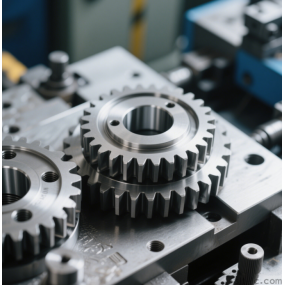

High-volume CNC machining refers to the production of 500+ identical metal or plastic parts using computer-controlled equipment. This process leverages advanced multi-axis CNC mills, lathes, and Swiss-type machines combined with optimized tooling strategies to achieve consistent results across large batches.

Key Advantages for Industrial Buyers

1. Cost Efficiency: Per-unit costs decrease significantly at scale due to amortized setup time and bulk material purchasing

2. Dimensional Consistency: Automated processes maintain ±.005" tolerances even across 10,000+ parts

3. Material Flexibility: Capability to machine aluminum alloys, stainless steels, titanium, and engineering plastics

4. Scalable Quality Control: Integrated CMM inspection and statistical process control protocols

EMAR's High-Volume Production Capabilities

Our CNC machining facility features 35+ CNC machines with pallet changers and robotic part handling systems specifically configured for mass production. We implement:

- Dedicated production cells for continuous operation

- Automated tool wear compensation systems

- Real-time production monitoring via IoT sensors

- Kanban-based inventory management for JIT deliveries

Industries We Serve

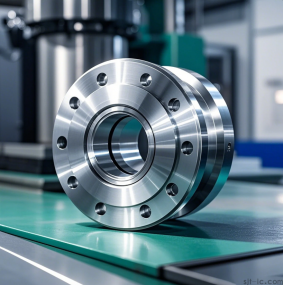

• Automotive: Engine components, transmission parts

• Aerospace: Structural brackets, hydraulic fittings

• Medical: Surgical instrument components

• Electronics: Enclosures, heat sinks, connectors

With ISO 9001:2015 certification and 12 years of high-volume manufacturing experience, EMAR delivers both the technical expertise and supply chain reliability that procurement professionals require. Contact our engineering team today to discuss your project's specific volume requirements and optimization opportunities.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque