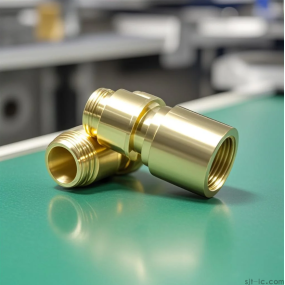

As a professional CNC Machining service provider, EMAR specializes in delivering high-precision connector components for industries ranging from electronics to aerospace. Our advanced manufacturing capabilities ensure tight tolerances, superior surface finishes, and reliable performance for mission-critical applications.

Why Choose CNC Machining for Connector Manufacturing?

Modern connectors demand micron-level precision that only CNC machining can consistently achieve. Our 5-axis CNC centers produce complex geometries with ±.005mm accuracy, including intricate threads, slots, and mating surfaces that ensure perfect electrical continuity and mechanical fit.

Material Expertise for Connector Applications

We machine all connector-grade materials:

Copper alloys (C11000, C17200)

Aluminum (6061, 7075)

Stainless steels (303, 304)

Engineering plastics (PEEK, PTFE)

End-to-End Connector CNC Machining Solutions

EMAR provides complete manufacturing services:

Prototype development (24-hour turnaround available)

High-volume production (50,000+ pieces/month capacity)

Secondary operations (plating, anodizing, laser marking)

Full metrology lab for quality verification

With ISO 9001:2015 certification and ITAR registration, EMAR guarantees connector components that meet MIL-STD, DIN, and other international standards. Contact our engineering team at www.sjt-ic.com for DFM analysis and instant quoting.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque